What's the difference between design automation and AI?

In today's fast-moving tech world, AI and automation tools are becoming more and more crucial for business. While some may fear the implications of AI, it's widely seen as a technology that can lead to breakthroughs that enable previously unthinkable achievements.

In the present day, there are many differences between design automation and AI. Despite these differences, both technologies share a common goal: they automate tasks that were once performed manually, and they simplify processes, reducing effort and reliance on specialized knowledge.

Comparing the differences

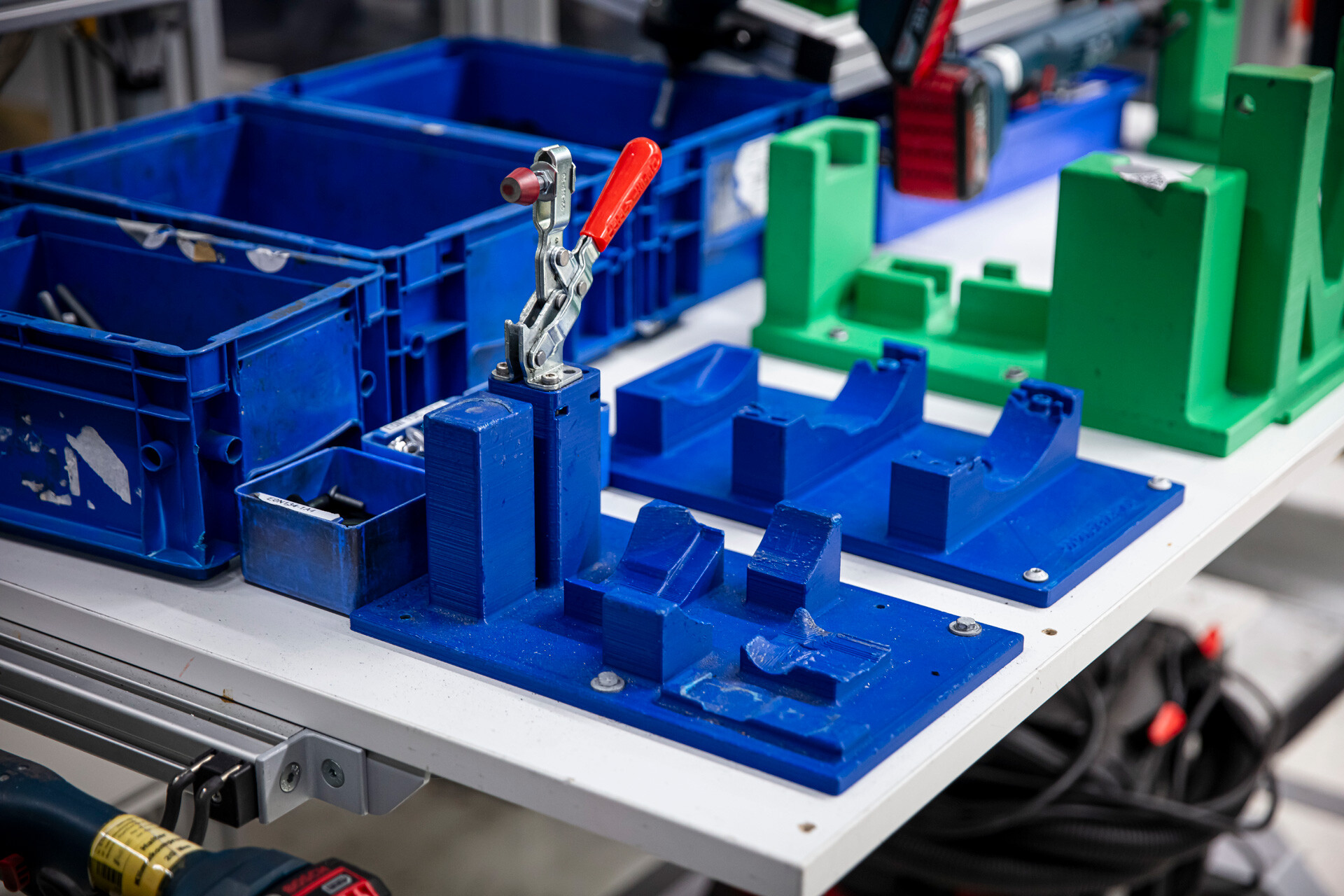

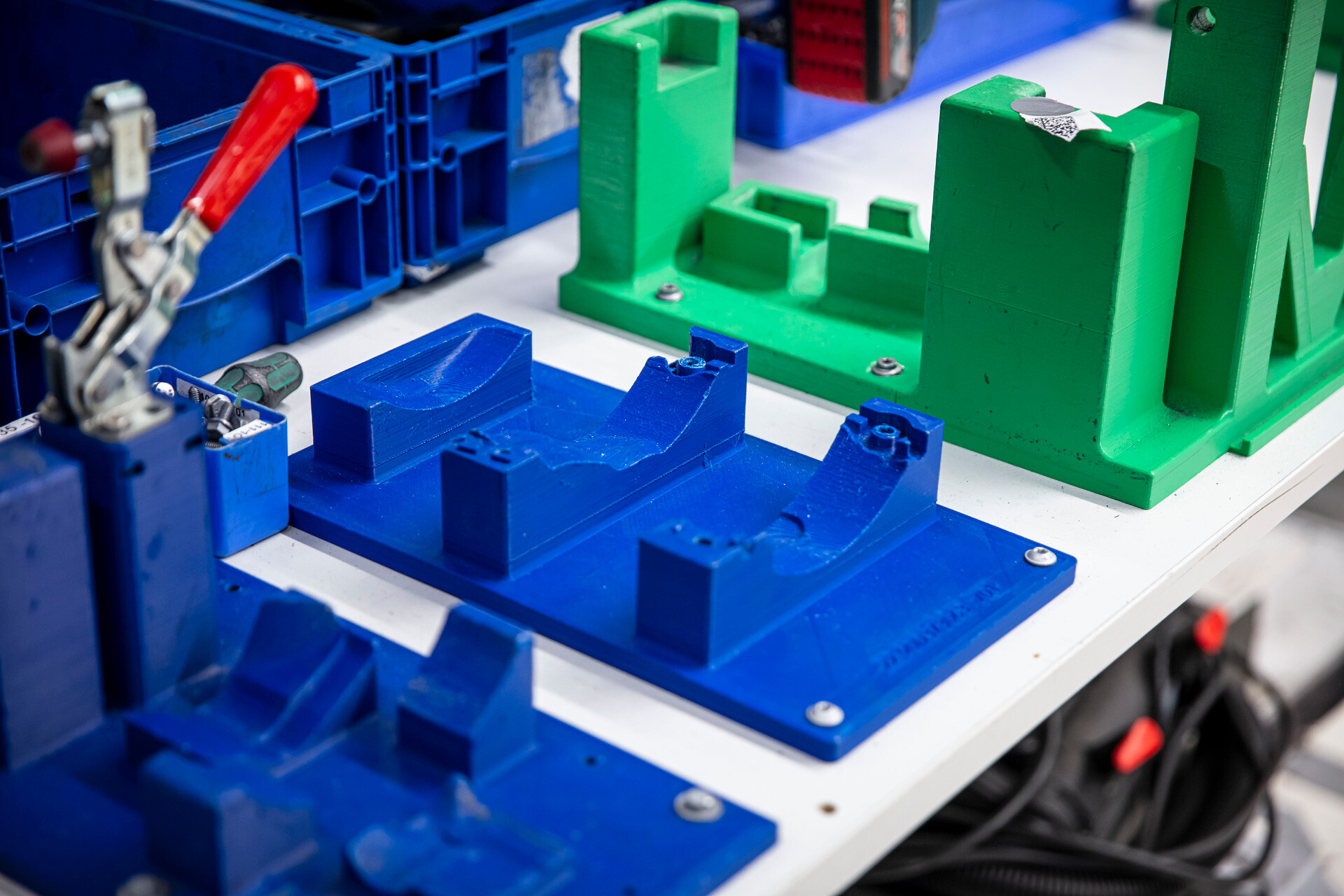

Integrating AI into design automation could lead to significant advancements. As AI algorithms become more sophisticated, they can enhance design automation tools by providing advanced problem-solving capabilities, predictive analytics, and optimization techniques. This integration would enable more efficient and innovative design processes, pushing the boundaries of what is possible in manufacturing and engineering. The potential for AI to learn and adapt means that design automation could become more intelligent, intuitive, and responsive to complex design challenges, bridging the gap between human creativity and automated precision. For example, it could be as simple as providing text instructions to an AI, which then generates a mesh in real-time before exporting a file ready for 3D printing.

Prospects of AI and design automation

One promising area where AI can realistically add value is mesh generation or modification. AI can be trained on vast datasets of existing mesh structures, learning patterns and characteristics that define optimal meshes for various applications. Once trained, the AI can predict and generate mesh structures based on specific input parameters, such as shape, size, and material properties. Through this, design processes which traditionally take several hours could be reduced into just minutes, without loss of detail or accuracy.

How could AI be implemented into design automation?

Extensive datasets of existing mesh structures could be collected, including their parameters and performance metrics. Machine learning techniques could then be used to train AI models on these datasets, focusing on recognizing patterns and predicting optimal mesh configurations. These trained AI models would be integrated into design automation software, allowing seamless interaction between AI and traditional design tools. A user-friendly interface would be developed where designers can input their requirements and receive AI-generated or modified meshes in real-time. Extensive testing would be conducted to ensure the AI-generated meshes meet performance and quality standards, with continuous refinement of the AI models based on feedback and new data.

What are the benefits of AI and design automation converging?

Integrating AI into design automation means increased efficiency, as the design process is sped up by automating mesh generation and refinement. The accuracy of the meshes is improved, leading to better overall product performance. Cost savings are realized through reduced material waste and production costs, and design time, and facilitating scalability in the design process, allowing for quick adjustments and iterations. It also enables more complex and innovative designs that might be difficult to achieve manually.

By implementing AI in mesh generation and modification, businesses can achieve significant advancements in their design processes, leading to more efficient, accurate, and innovative products.

Learn more about design automation

We develop both off-the-shelf and custom design automation software to help the automotive, manufacturing, and medical industries optimize their design and production workflows.

Explore our use cases to see practical applications, learn more about design automation from our detailed guides, or contact our team for personalized advice and demonstrations.