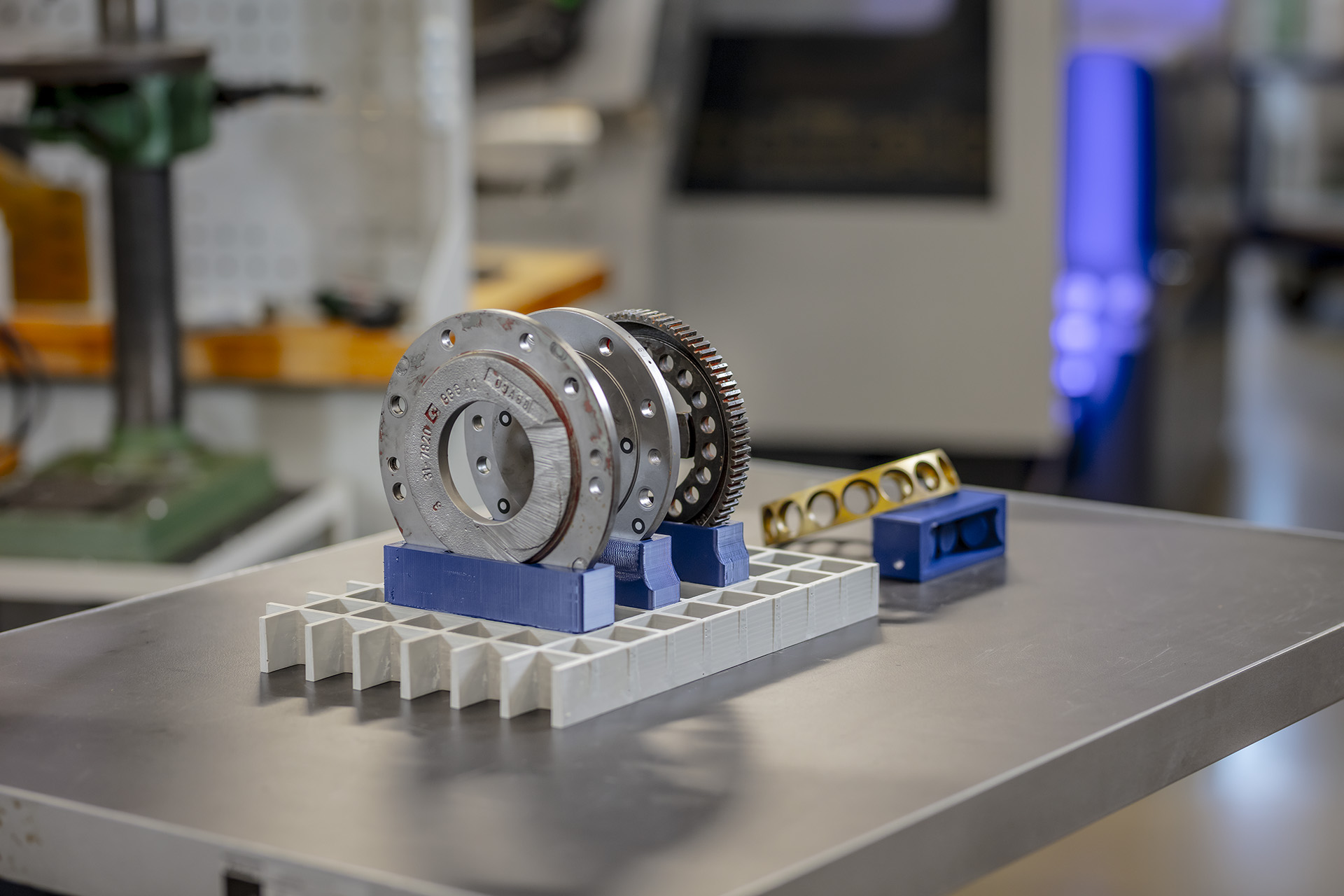

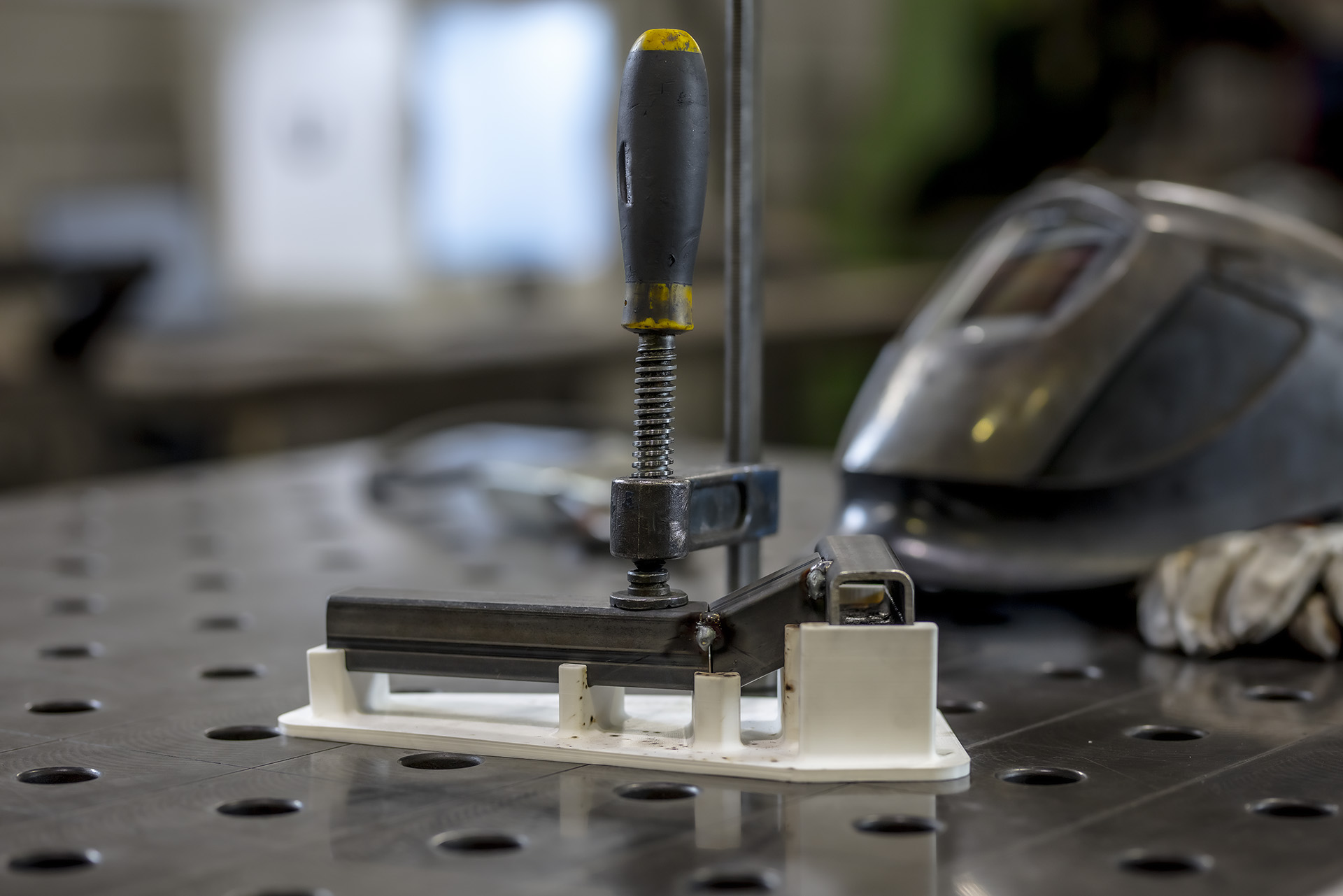

In industries ranging from electronics and automotive to pharmaceuticals and food processing, carrier trays are an indispensable tool. They are specialized containers or trays used as reliable carriers for various components, ensuring safe and organized movement throughout a facility. They facilitiate smooth and streamlined internal logistics are crucial for optimizing operations and reducing handling time.

The benefits of carrier trays

Enhanced organization. By providing dedicated spaces for components, carrier trays help keep items neatly arranged and easily identifiable, reducing the risk of misplacement or loss.

Improved material handling. Trays simplify the movement of components, making it easier for operators to load, unload, and transport items efficiently within the facility.

Space optimization. Carrier trays are designed to fit specific components, optimizing the use of available space during internal logistics operations.

Cost savings. With improved organization and efficient material handling, carrier trays help reduce the risk of damaged items and minimize the need for replacements, leading to cost savings.

Time efficiency. Trays streamline material handling processes, reducing the time spent searching for components and optimizing workflow within the facility.

Customizability. Carrier trays can be designed to accommodate various component sizes and shapes, making them adaptable for a wide range of internal logistics tasks.

Stackability. Many carrier trays are stackable, allowing for efficient storage and maximizing floor space within the facility.

Enhanced safety. Carrier trays provide secure containment for components, reducing the risk of accidents during material handling and transportation.

Real-world applications. Carrier trays are widely used in industries such as electronics, automotive, and pharmaceuticals, where effective internal logistics is critical for production efficiency.

Sustainability. Reusable carrier trays contribute to sustainable practices by reducing the need for single-use packaging materials.

How could design automation help you?

Carrier trays play a crucial role in optimizing internal logistics and material handling processes. You can optimize the design process for these trays using our web-based design automation software. Simply input your component specifications, and the software takes care of the rest. No CAD expertise is required.

Discover how our design automation software can help you get the design results you want in half the time or less.

Explore related articles

Design automation in use: Bonding and welding fixtures

Design automation in use: Inspection gauges