Guide: Design automation for CAD experts

Introduction

CAD software stands as a fundamental tool in modern manufacturing. It fits into many industrial scenarios and comes with a wide array of advanced features.

However, mastering it for commercial use demands years of extensive learning and practice, and in use it often involves multiple, repetitive, time-consuming steps when working with components and assemblies.

In this article, we’ll explore how design automation can save time for CAD experts and can help share the design burden among people with zero CAD experience. When onboarded with a design automation platform, these people are empowered to produce useful designs with ease and efficiency, and for the benefit of a whole organization.

Key takeaways

-

Design automation significantly speeds up product development by automating repetitive CAD tasks, reducing design costs and making industrial design more accessible to those without extensive CAD experience.

-

Automating manual CAD tasks increases efficiency and design accuracy through rule-based algorithms, enabling rapid customization and improving team collaboration.

-

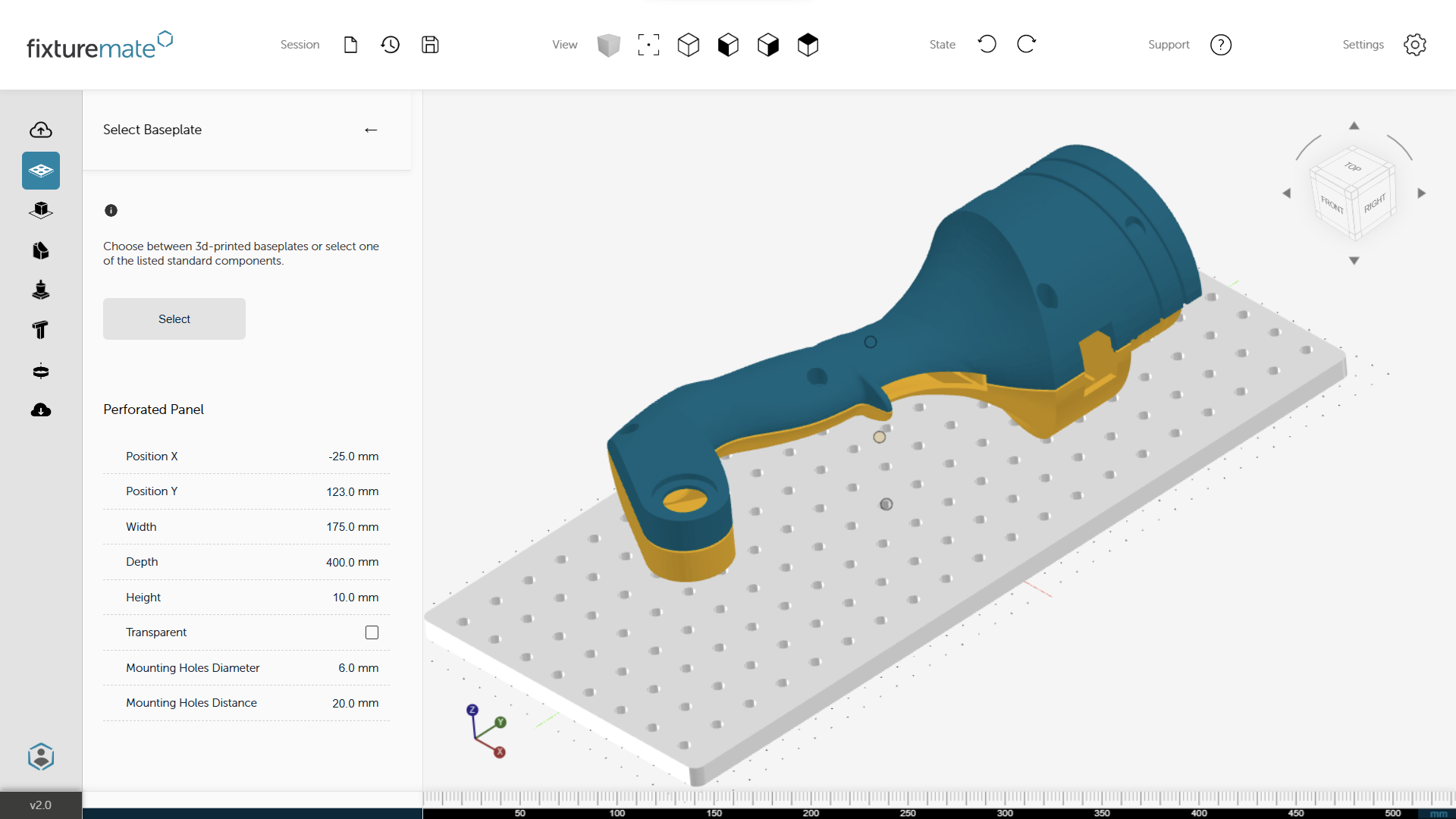

Design automation software such as fixturemate addresses common bottlenecks in product development, especially in designing custom manufacturing aids like fixtures, by enabling more stakeholders to contribute to the design process without needing CAD expertise.

-

With the user-friendly interfaces and rule-based algorithms design automation brings, even individuals with no CAD background can quickly create and adjust designs, which democratizes the design process and allows for greater flexibility and scalability in projects.

Overcoming common design challenges

Time equals money in commercial product development, and design automation offers vital solutions. It makes it possible to streamline the product development cycle, speeding up design realization by automating the repetitive, manual steps involved in CAD processes, which in turn cuts down design costs for businesses.

Experienced designers can delegate more routine, lower-priority design tasks to a secondary group, who don't need expertise in CAD software. Rule-based algorithms enable beginners to rapidly create and adjust designs to meet industrial standards. In addition, the user-friendly and intuitive interfaces of design automation tools significantly lower the steep learning curve often associated with advanced CAD software, making industrial design more accessible to a broader range of users.

Beyond making industrial design more accessible to those without extensive CAD experience, design automation offers significant benefits to CAD experts as well. The key advantages are summarized below:

-

Boosted efficiency by automating repetitive manual CAD tasks

-

Better design accuracy, driven by rule-based algorithms

-

Rapid product customization

-

Clearer internal design communication and greater collaboration within teams

-

Empowers a wider range of stakeholders to engage in product design

-

Greater flexibility and scalability to accommodate a variety of different projects

Product development cycles often face bottlenecks when designing essential manufacturing aids, such as fixtures. These highly customized tools securely hold and position workpieces during assembly and measuring operations, which reduces waste, keeps products consistent, and a range of other benefits. Fixtures are typically low-volume items which are tailored to the various components of a product. To be viable tools, they need robust properties, as they will be on a production floor and can expect to be used hundreds or even thousands of times when their corresponding product goes into production.

Fixture design is notoriously time and resource intensive, even for experienced designers. In many cases, the design effort for fixturing a product in development can take more time to design than the product itself. The responsibility of fixture design typically falls on the shoulders of skilled design teams, which means they are diverted away from higher-priority, creative challenges that their time would be better spent on.

In design projects, input is often needed from people who aren’t skilled in CAD software. Designers then have the task of understanding these suggestions and turning them into practical design features. This process involves a lot of changes and fine-tuning, which is essential for developing a good product. However, it can also lead to confusion and miscommunication. These misunderstandings can slow down the project, make collaboration more difficult, and, ultimately, increase the design costs for the company.

Design automation is a great solution for these widespread manufacturing challenges. It's all about making design processes more efficient and letting more people contribute to the design. Why does this matter? Because it leads to products being developed faster and to a higher quality.

A primary design team can customize the design automation system with specific rules and user-friendly interfaces that meet their organization's unique needs. These interfaces are much simpler than the complex ones found in industry standard CAD software, making design more accessible to those with no CAD skills.

Design automation makes industrial design accessible to a wider range of users

We’ve encountered customers in automotive manufacturing who use design automation strategically, especially when their top-tier design talent is focused on high-priority business tasks. In times of resource constraints, they can shift some design responsibilities to a secondary group of users. These users, being closer to the application, often have insights more aligned with the design's purpose and intent. For example, a manufacturing operations team can use a design automation application like fixturemate to create and modify tools they use daily for their work. This could involve designing workholdings, adding ergonomic handles to tools, or creating custom gauges that speed up their work rate. Design automation provides them with a degree of independence in design, eliminating the need for involvement from the primary design team.

These designs can be produced quickly and locally on affordable 3D printers, using materials robust enough for a workfloor environment. This quick turnaround is a major advantage over traditional tooling processes, which often take weeks or longer. As a result, substantial time savings translate directly into cost savings.

The rollout of such a system might look like this:

-

The primary design team sets up the design automation interface, creates initial base models, and establishes essential design guidelines.

-

The primary design team conducts a brief training session to introduce the secondary design team to the system.

-

Once onboarded, the secondary design team gains the capability to develop their own fixtures autonomously.

-

The secondary design team proceeds to independently craft their custom tooling solutions.

-

The designed fixtures are then 3D printed and put into operation.

-

Any necessary design refinements are carried out by the secondary team based on usage and feedback.

-

Throughout the process, the primary design team maintains oversight and provides assistance as needed.

Of course, there’s no cap on how many secondary design teams there can be within an organization. The advantage of design automation is it is adaptable to many different unique manufacturing scenarios. Because it’s software, it’s constantly improving, and because it's web-deployed, it's always up-to-date, eliminating the need to uninstall and reinstall different versions.

Intuitive interfaces help to bridge the design skills gap

How does design automation work?

Design automation uses software to automate design tasks that are traditionally performed manually in CAD software. Powerful algorithms operate within a set of predefined rules, which can be applied to everything from simple components to complex assemblies. The goal of design automation is to reduce repetitive manual tasks, eliminating errors and accelerating the design phase, ultimately contributing to a more efficient and cost-effective manufacturing process.

At the heart of a design automation system are rule-based algorithms. Rulesets can be configured by a primary design team which keeps all design output to a high level of quality and accuracy. These algorithms can also control business-specific characteristics of the product so designs are aligned with specifications or other industrial standards. Some examples of design workflow steps you can automate using design automation:

-

Adding preset-sized holes to designs with a single click

-

Embossing or engraving custom text, logos, or identification codes like RIC marks

-

Enabling quick customization of base designs for specific requirements or customer specifications

-

Easily subtracting complex geometries to create nested designs and cutaways

-

Inserting standard components like screws, bolts, and clamps instantly, bypassing manual design of these components

-

Automatically applying design features such as fillets and chamfers

-

Checking geometry for potential issues and interferences

-

Fine-tuning mating component offsets for optimal part fit

-

Extending features like bosses to the nearest object in one step

-

Adding standardized mounting points with pre-cut holes in a single step, instead of multiple steps

-

Rapidly reconfiguring complex assemblies based on simple inputs like mouse clicks

-

Automatically generating essential product documentation, such as drawings and assembly instructions

-

Conducting ‘pre-flight’ checks before 3D printing to optimize part geometry and process reliability

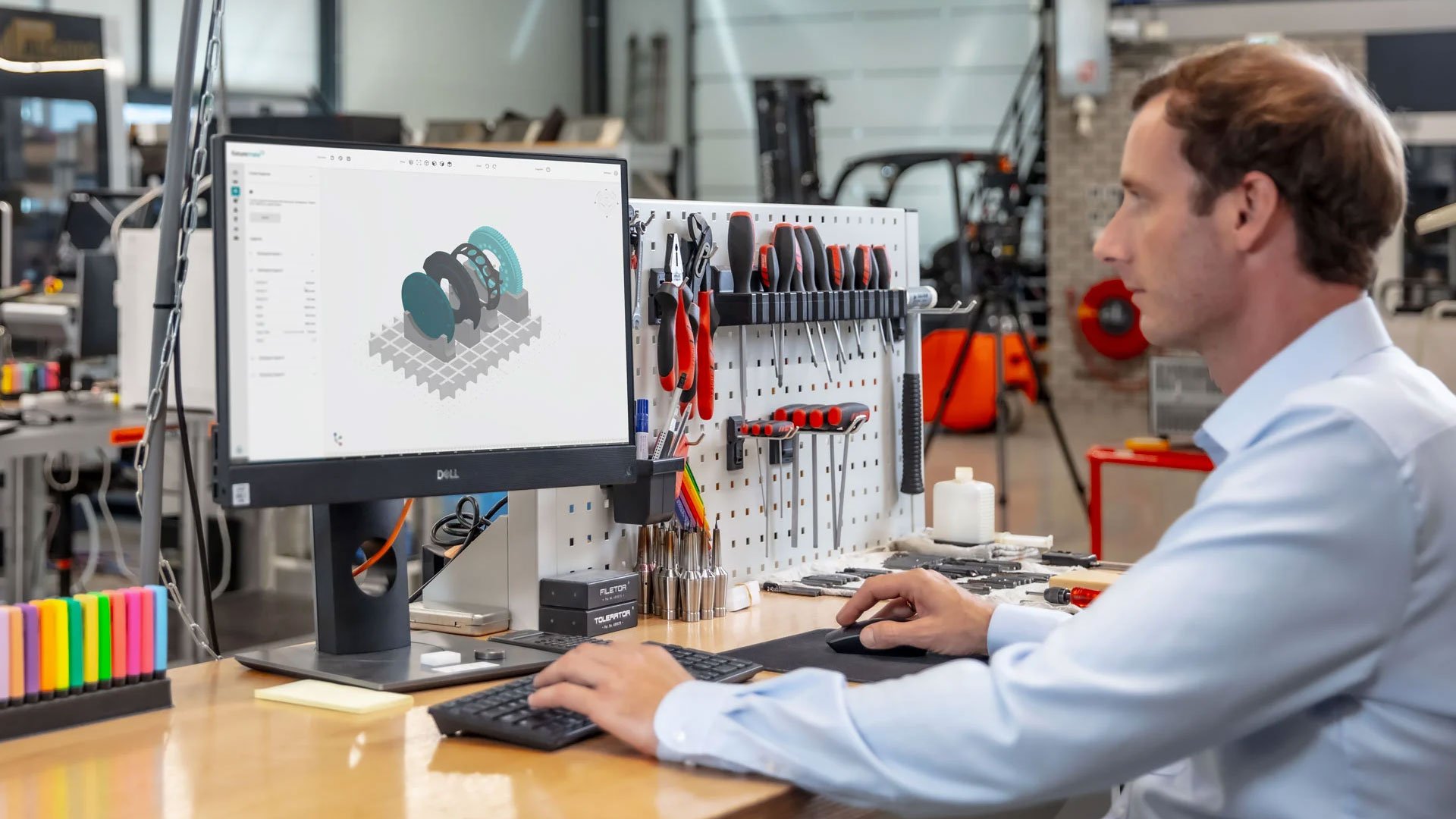

Below is a simple example of a design automation application in action. In this example, the user places three contact points on an object, which will then automatically configure a robot gripper assembly. Traditionally, this would be a long process for an experienced design engineer. With design automation, it's ready in a few clicks, and there's no need for CAD skills.

Those familiar with CAD will probably be quick to notice that design automation applications share basic UI elements found in standard CAD software, like a 3D scene.

Interfaces can be configured to meet user needs, including the implementation of elements such as toolbar buttons for model manipulation and camera control tools. This ensures a seamless transition for users already familiar with conventional CAD tools and ease of use for those new to CAD tools.

It's also possible to streamline tasks peripheral to the design process, such as automating metadata imports (e.g., CSV data) and generating documentation (like PDFs). This workflow simplification reduces the need for repetitive context-switching tasks between different software platforms, leading to a significant quality of life improvement for users.

In the next section, we’ll explore some use cases to illustrate the benefits of this approach.

fixturemate is design automation software that makes the process of fixture design faster and more intuitive

Design automation enables mass customization of products without manual steps

PROTIQ, a specialist in copper inductors for induction heating, transformed its manufacturing process by adopting design automation. Traditional, time-consuming CAD tasks were replaced with a configurable system, enabling around 20 adjustable parameters for tailoring inductor geometry. Hosted on an easy-to-use web application, this system allows customers to design and order custom inductors effortlessly, without needing CAD expertise. This shift not only made the production process more efficient but also expanded the possibilities for scalable manufacturing.

PROTIQ's configurator offers 20 adjustable parameters for customizing inductor geometry, while ensuring functionality and printability

Design automation can optimize designs fast

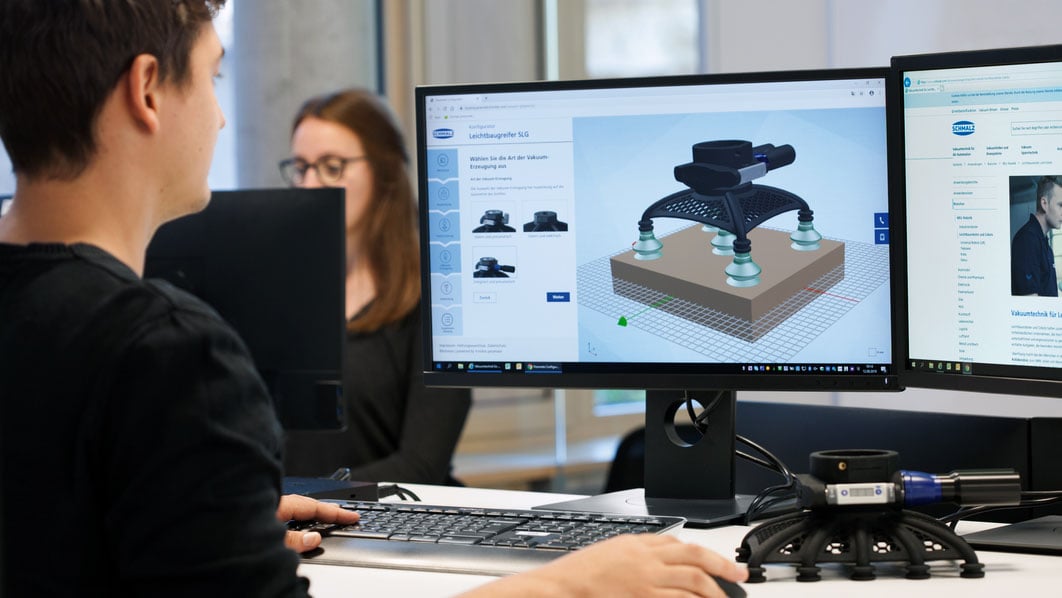

J. Schmalz GmbH streamlines vacuum gripper design with trinckle's paramate engine, transforming a day-long task into a 10-minute, user-friendly online process. This platform on Schmalz's website allows customers and employees globally to customize grippers by defining tasks and specifications, including 3D models, with intuitive guidance and algorithmic optimization. No CAD expertise is needed, and users receive a CAD model and quote quickly, ensuring designs meet specific automated industrial needs.

Combining user-friendly configuration, instant CAD model generation, and 3D printing, this approach reduces design time to mere minutes

Design automation can streamline automotive production workflows

Ford Motor Company's adoption of design automation allows assembly line workers to design tools at the expertise level of CAD professionals, optimizing and deploying each tool in less than a week. This strategy not only reduces complexity and time in the design process but also enhances overall production efficiency.

Ford plans to expand this automation approach across its range of 3D printed tools, leveraging the many benefits of additive manufacturing to boost productivity in its manufacturing processes.

Ford has successfully integrated over 50 different 3D printed tools in its production, yielding immediate cost savings and efficiency gains

What does the future hold for design automation?

The manufacturing industry is changing rapidly, and staying adaptable to shifting market headwinds is key. Below are some of our predictions for design automation’s position in the future of manufacturing:

Deeper integration with CAD software. We notice a slow convergence between CAD systems and slicing software for 3D printing. We expect to see further integrations between separate software applications in the design workflow. Our software can be configured to bridge many of these gaps, keeping things productive and minimizing frustration from switching between competing applications.

Low barriers to design entry. Designing any object will become so intuitive, it will be as simple as sending email or scrolling an app on a phone, and anyone will be able to translate their ideas into practical designs.

More cloud-based collaboration platforms. As the remote-first working culture gains prevalence, design automation will become a hub to facilitate real-time teamwork across geographical distances.

More mass-customized products. Production processes streamlined by design automation will make it easier and cheaper to customize base products specific industry needs and a customer’s individual preferences.

Sustainability. Design automation will find applications in a broader range of applications and industries, incorporating sustainability considerations and optimizing products to be more environmentally friendly.

Design automation unlocks creativity and efficiency

The integration of automation in design processes represents a significant leap forward in both efficiency and creativity. The traditional approach to design, particularly for frequently needed and often-modified items like fixtures, can be incredibly time-consuming, often involving tedious, repetitive tasks and extensive back-and-forth communication for iterations. By automating these aspects, not only is a substantial amount of time saved, but we also see a notable improvement in the output's quality, consistency, and reliability.

Empowering secondary groups to take charge of their own design modifications further streamlines the process. This approach reduces bottlenecks and fosters a more collaborative and responsive design environment. This shift in approach frees up valuable time for designers, allowing them to focus on more advanced projects that demand a higher level of creativity and innovation. Design automation enables an organization to enhance the design process's efficiency while elevating the final product's quality. This balance between productivity and innovation is key to staying competitive and relevant in an ever-evolving market.

Go further with design automation

For a comprehensive understanding of design automation, we invite you to read our Introduction to design automation article. Or if you're looking to introduce someone with limited CAD experience to the advantages of design automation, our Design automation for CAD novices article is the perfect resource.

We’re here to equip CAD experts with more efficient, versatile, and accessible tools which enable them to focus more on the creative and problem-solving aspects of their work.

If you want to find out more about custom design automation solutions we can provide, get in touch with one of our experts today.