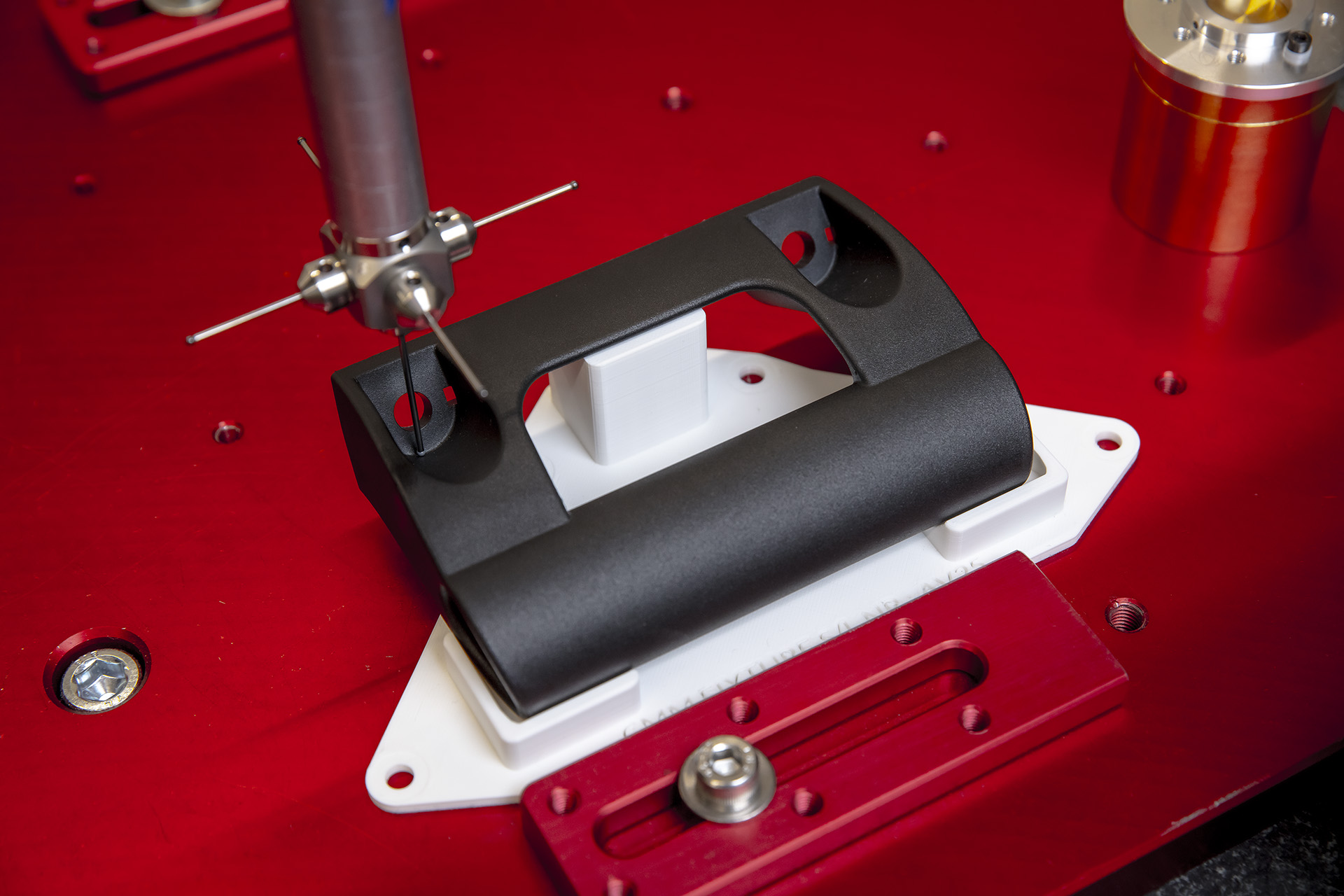

Ensuring the quality and accuracy of manufactured parts is crucial for various industries. Inspection gauges are specialized tools used to precisely measure and verify the dimensions and tolerances of workpieces during quality control processes. They act as reliable instruments for inspectors and quality assurance personnel, helping them assess whether the parts meet the required specifications.

Inspection gauges find applications in diverse fields, from automotive to medical devices, where strict adherence to quality standards is essential for customer satisfaction and safety.

The benefits of using inspection gauges

Enhanced accuracy. By providing precise measurements, inspection gauges ensure the accurate assessment of workpiece dimensions and tolerances, reducing the risk of defective products reaching the market.

Improved quality control. Gauges help maintain consistent product quality by identifying variations in dimensions and tolerances, allowing timely corrective actions to be taken.

Cost savings. With enhanced accuracy and quality control, inspection gauges help reduce material waste and rework, leading to cost savings in the manufacturing process.

Ensured compliance. Gauges ensure that manufactured parts meet the required industry standards and specifications, ensuring compliance with regulations and customer expectations.

Efficient inspection processes. Inspection gauges facilitate quick and efficient measurement procedures, reducing inspection time and increasing overall productivity.

Customizability. Gauges can be designed to accommodate various workpiece geometries, making them adaptable for a wide range of inspection tasks.

Advanced measurement capabilities. Some inspection gauges may include advanced features, such as digital readouts or automated measurements, enhancing the accuracy and efficiency of inspections.

Real-time feedback. Gauges provide real-time feedback to operators, enabling immediate adjustments during the manufacturing process, reducing defects and rework.

Reliability in critical industries. In industries where precision and safety are paramount, such as aerospace and medical devices, inspection gauges play a crucial role in ensuring product integrity.

Improved data analysis. Inspection gauges generate valuable data that can be analyzed for process improvement and optimization, enhancing overall manufacturing efficiency.

How could design automation help you?

Inspection gauges play a vital role in maintaining product quality and adherence to specifications. You can optimize the design process for these gauges using our web-based design automation software. Simply input your workpiece and change some basic settings, and the software will produce a useable gauge in minutes. No CAD expertise is needed.

Discover how our design automation software can help you get the design results you want in half the time or less.

Explore related articles

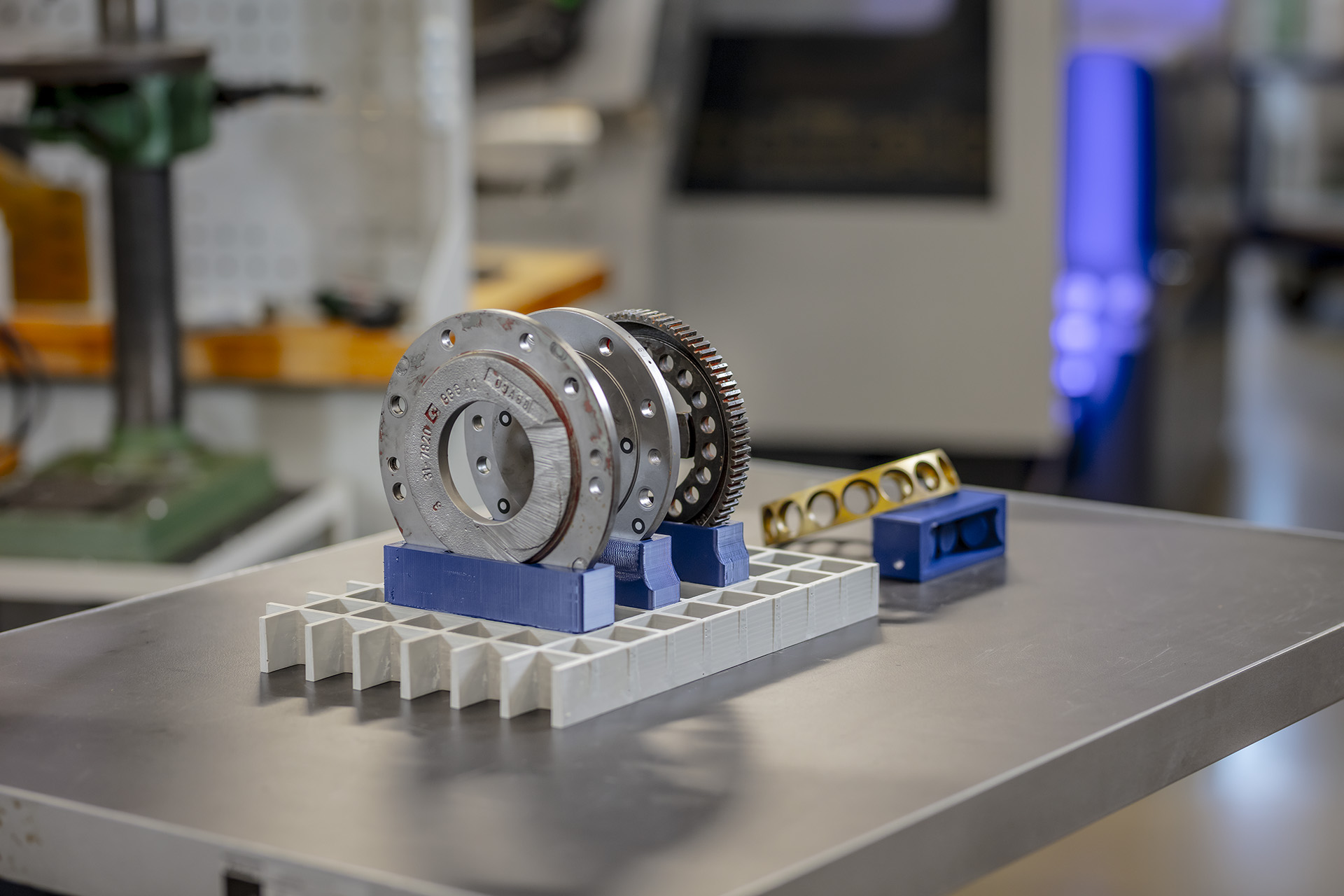

Design automation in use: Carrier trays

Design automation in use: Machining fixtures