What is a machining fixture?

In manufacturing, various operations like cutting, drilling, milling, or shaping are performed on workpieces to create the final product. A machining fixture acts like a helpful guide, ensuring that the workpieces remain in the right positions and orientations, so machines can work on them accurately and consistently. Think of it as a tool that acts like a third hand for the workers, making their job easier and allowing them to achieve precise results.

Machining fixtures are used across different industries, from automotive to aerospace, where precision and efficiency are crucial in producing high-quality products. Without these fixtures, it would be challenging and time-consuming to create complex and accurate parts.

The benefits of machining fixtures

Improved precision. By securely holding and positioning workpieces, machining fixtures ensure consistent and precise machining operations. This results in accurately manufactured parts with tight tolerances, reducing errors and rework.

Increased efficiency. Fixtures enable faster and more streamlined production since workers can quickly load and unload workpieces. The repeatable setup saves time, allowing for higher production rates.

Cost savings. With enhanced precision and efficiency, machining fixtures help reduce material waste and decrease the need for manual adjustments, ultimately lowering production costs.

Enhanced safety. Fixtures provide a stable and secure platform for workpieces, reducing the risk of accidents and injuries to workers during machining operations.

Consistency and quality. The use of fixtures ensures consistent machining results across multiple workpieces, maintaining a high level of product quality throughout the production process.

Versatility. Fixtures can be designed to accommodate various shapes and sizes of workpieces, making them adaptable for a wide range of manufacturing tasks.

Complex operations. For intricate or complex machining operations, fixtures offer the stability needed to execute precise cuts and operations that may not be possible with manual holding.

Flexibility in automation. Machining fixtures are compatible with automated manufacturing systems, enabling seamless integration into computer-controlled production lines.

Shorter setup times. With repeatable setups, switching between different workpieces becomes quicker and more efficient, reducing downtime and increasing overall productivity.

Long-term savings. Although machining fixtures require an initial investment in design and fabrication, their long-term benefits in terms of increased productivity and reduced rework make them cost-effective over time. Fixturemate can accelerate the design process by automating key design features, and 3D printing can bring fabrication in-house, shrinking the cost of manufacturing.

How could design automation help you?

Overall, machining fixtures play a crucial role in modern manufacturing by ensuring accuracy, efficiency, and consistency, leading to improved product quality and reduced production costs.

You can automate the design of these parts quickly and easily using fixturemate, our web-based design automation software. All you need is the part you need to fixture. Just input some basic settings, draw simple shapes using your mouse, and the software will produce a practical custom design that can save you a good chunk of time and money.

Discover how our design automation software can help you get the design results you want in half the time or less.

Explore related articles

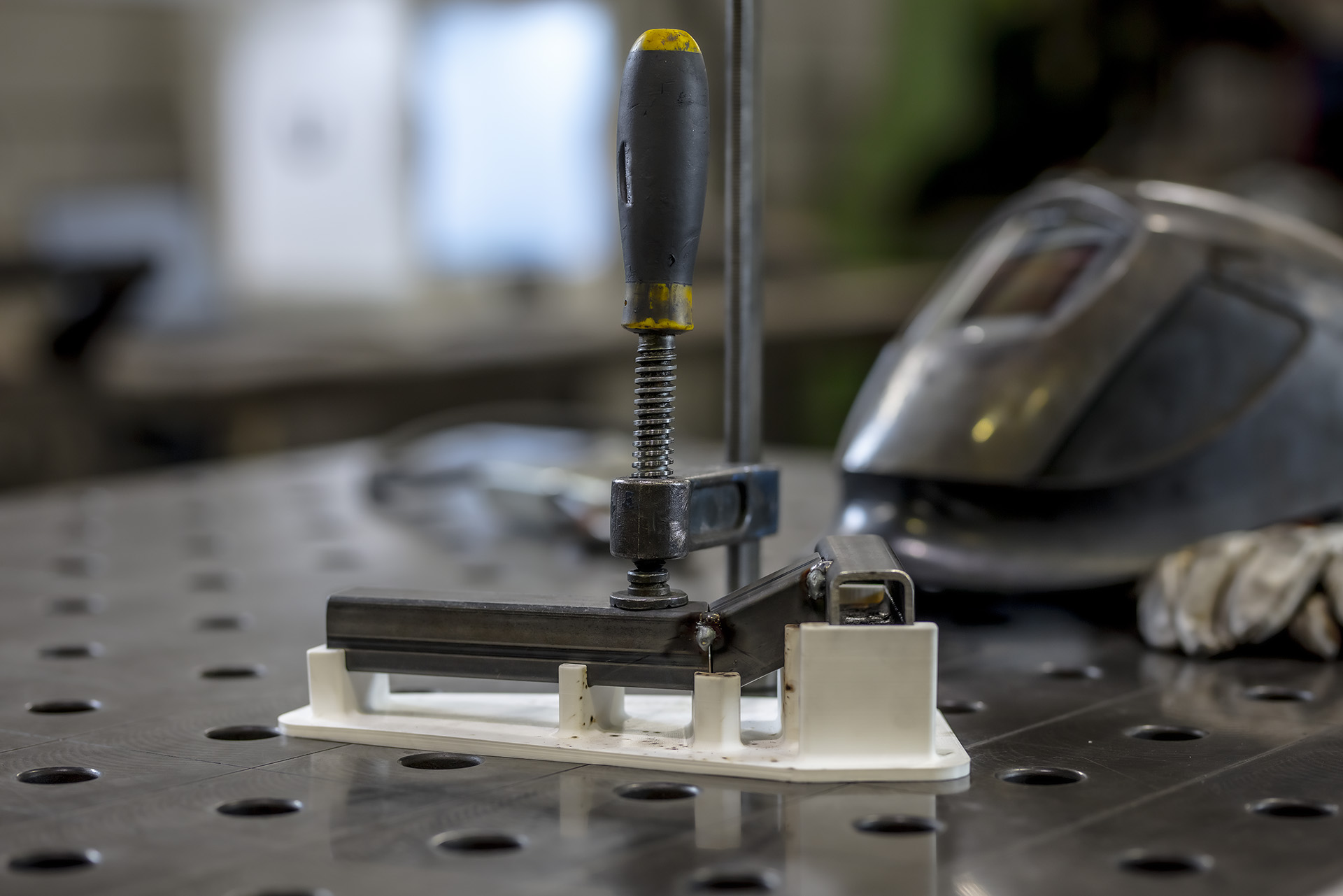

Design automation in use: Bonding and welding fixtures

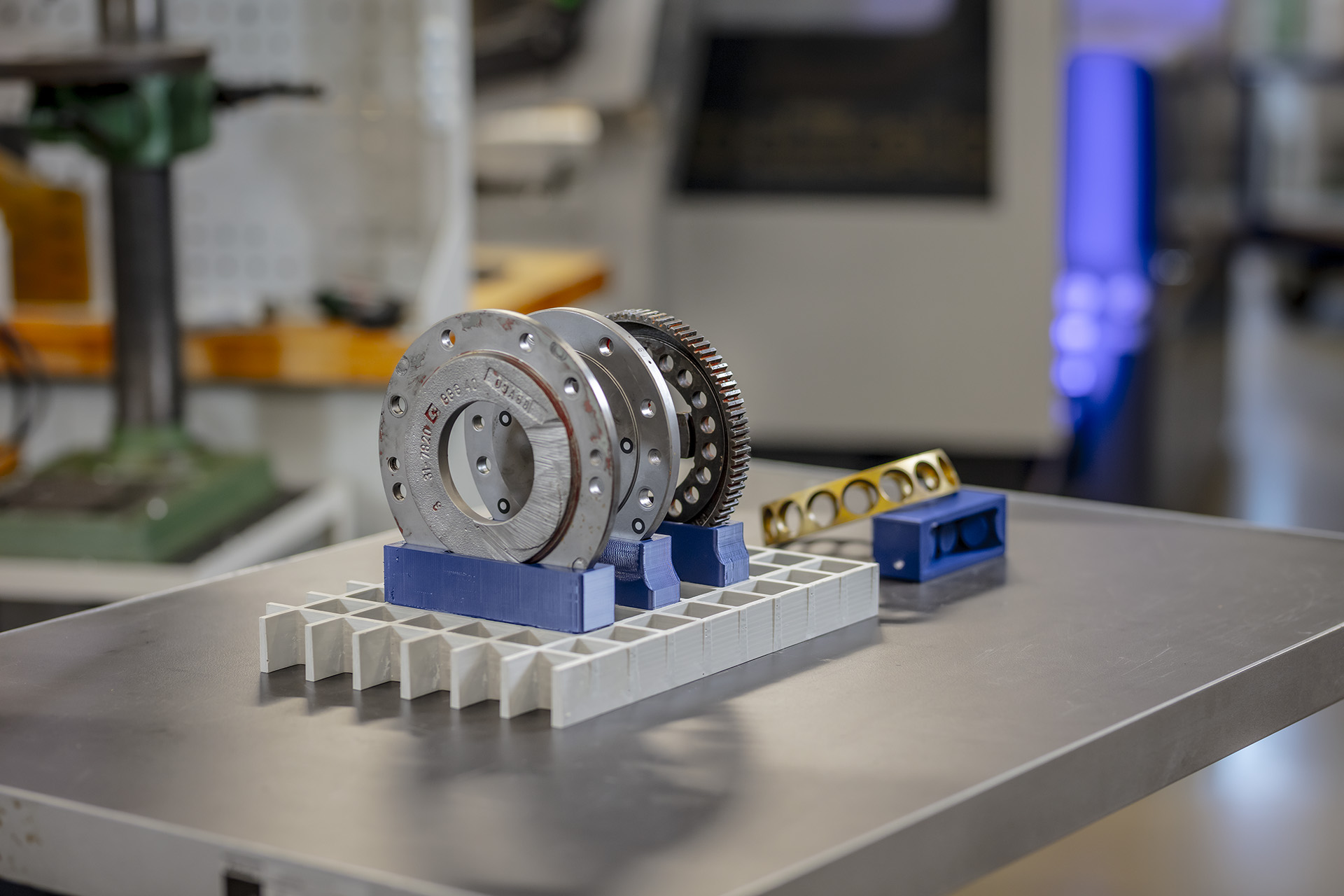

Design automation in use: Carrier trays