Precise measurements are crucial for ensuring the quality and accuracy of products in a range of different industries.

Measuring fixtures are specialized tools used to securely hold and position workpieces during measurement processes. They act as reliable guides, guaranteeing that the workpieces are in the correct positions and orientations, facilitating accurate and consistent measurements.

Measuring fixtures find applications in diverse fields, from manufacturing to engineering, where precise and repeatable measurements are essential for meeting strict quality standards.

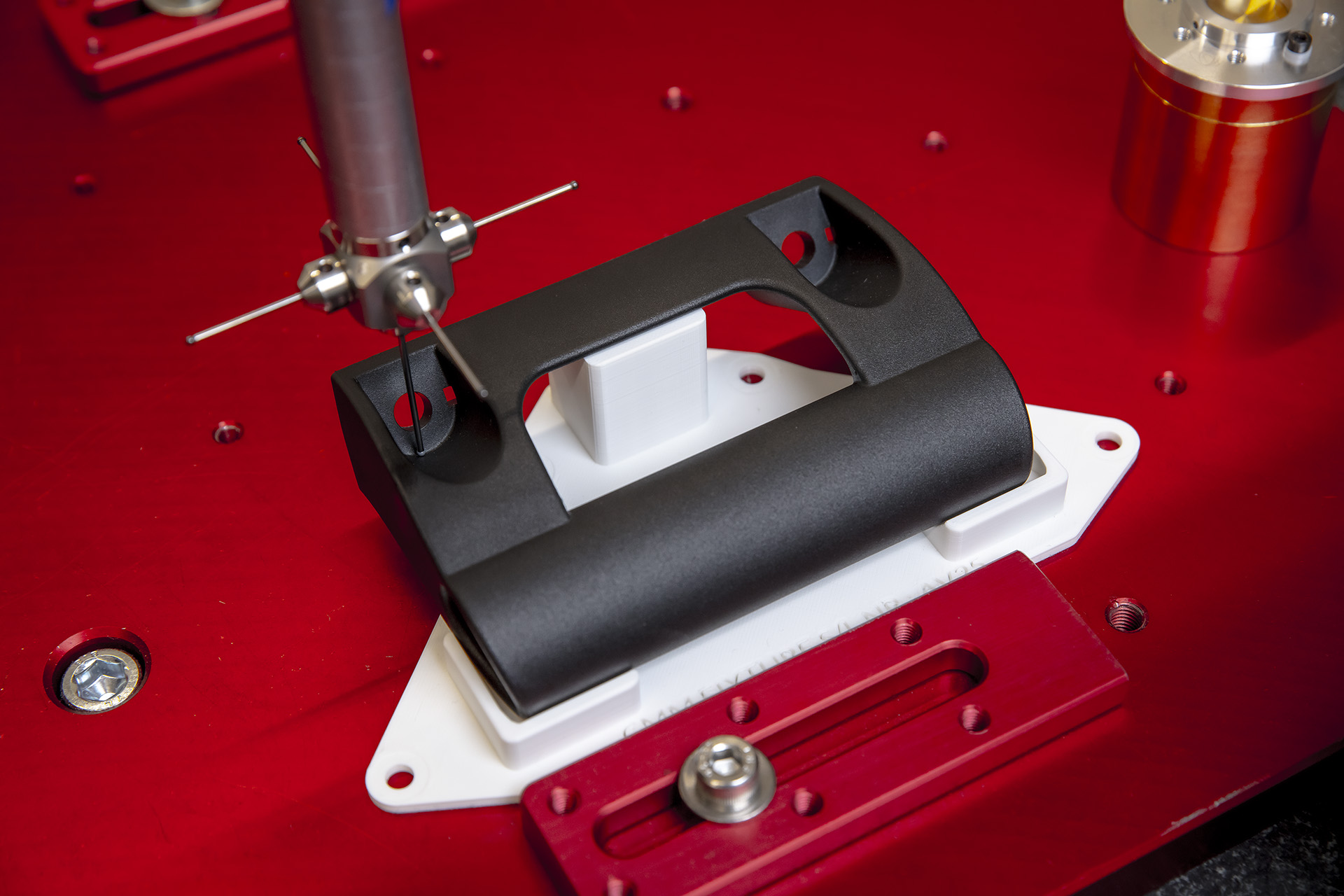

This 3D printed CMM fixture (white) is used to keep workpieces firmly in place for measuring operations

The benefits of measuring fixtures

Measuring fixtures offer several significant advantages in the measurement and quality control processes:

Enhanced precision. By securely holding workpieces in place, measuring fixtures ensure consistent and precise measurements. This leads to accurate and reliable data, reducing measurement errors and improving product quality.

Improved efficiency. Measuring fixtures streamline the measurement process by allowing easy positioning and rapid loading and unloading of workpieces. This increases the overall efficiency of the measurement operations.

Cost-effective. The use of measuring fixtures can reduce measurement times, which translates to cost savings. Moreover, precise measurements help identify defects early, minimizing the need for costly rework.

Ensured safety. Measuring fixtures provide a stable platform for workpieces during measurements, reducing the risk of accidents and ensuring the safety of workers.

Consistency and standardization. Measuring fixtures ensure uniformity in measurements across multiple workpieces, maintaining a high level of quality control throughout production.

Adaptability. Fixtures can be designed to accommodate various shapes and sizes of workpieces, making them suitable for a wide range of measuring tasks.

Complex measurements. For intricate or irregularly shaped workpieces, measuring fixtures offer stability and precision, enabling accurate measurements that may be challenging to achieve with manual methods.

Integration with automation. Measuring fixtures are compatible with automated measurement systems, enabling seamless integration into computer-controlled measurement processes.

Shorter setup times. With repeatable setups, switching between different workpieces becomes quicker and more efficient, reducing downtime and increasing overall productivity.

Long-term benefits. Despite the initial investment in design and fabrication, measuring fixtures prove cost-effective over time due to increased productivity and reduced measurement errors.

Measuring fixture examples

Jydsk Aluminium Industri – also known as JAI – is a prominent gravity die casting foundry in Europe, operating from its headquarters in Denmark. The company specializes in developing aluminum casting parts for various industrial applications, including automotive, high-voltage systems, pump systems, robots, maritime engines, and drive systems. For these industries, the precision of parts is critical, making measuring fixtures essential to maintain streamlined production.

A measuring fixture can be as simple as pulling a part off the production line and placing it into a fixture. If it fits well, the part is within specification, and can proceed. If not, it is rejected.

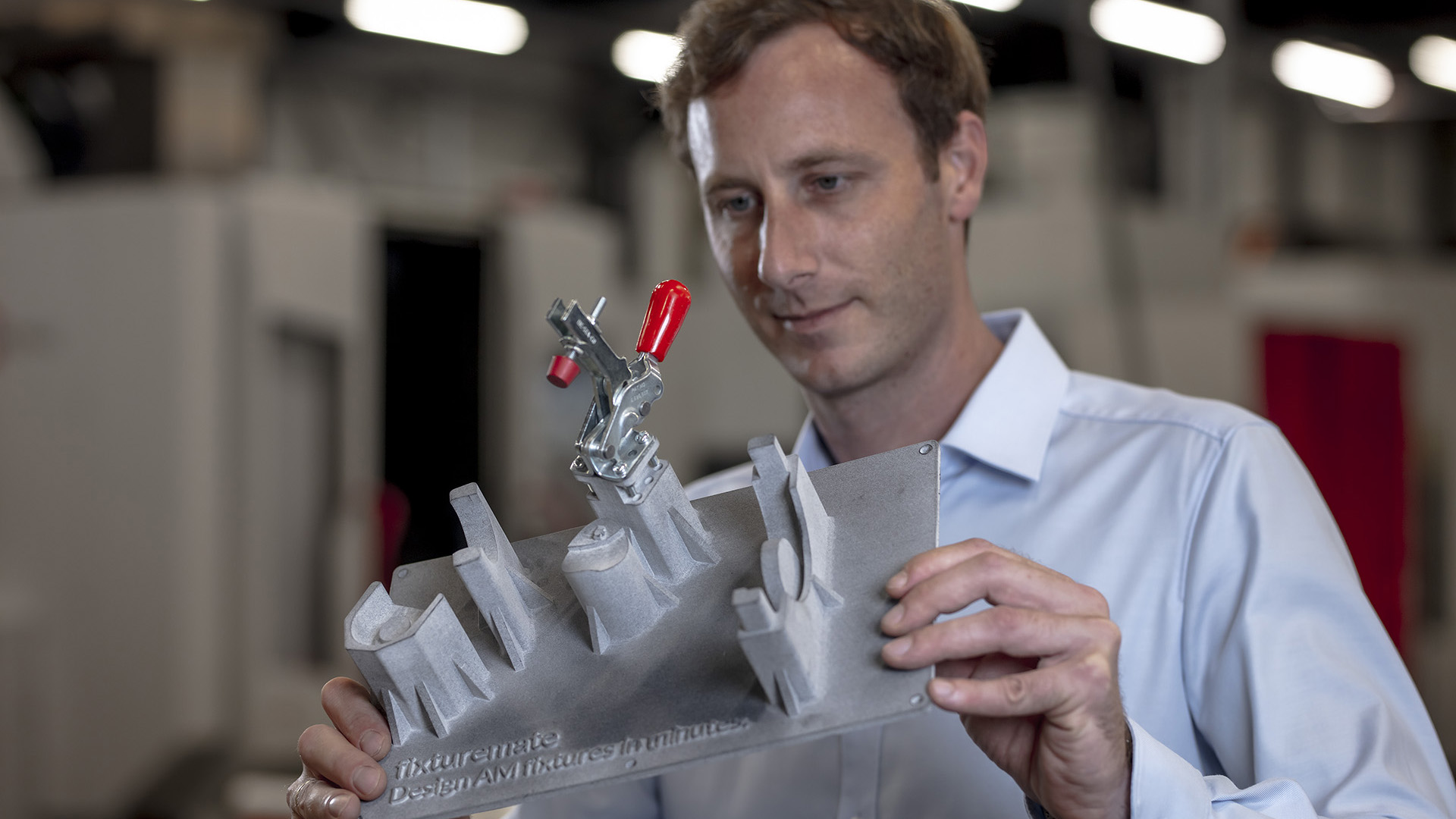

In the past, the process of producing custom tooling for complex products fell upon the core design team, who were already occupied with designing the parts themselves and corresponding production tooling. However, with the introduction of design automation through fixturemate, JAI gained greater flexibility in creating measuring fixtures. This shift allowed the core design team to concentrate solely on part design while transferring production tooling responsibilities to other teams.

One significant advantage of fixturemate was its user-friendliness and independence from CAD design skills or knowledge of DfAM (design for additive manufacturing). JAI's quality assurance engineers were able to produce their own inspection and production tooling, with repeatable, dimensionally-accurate results. This approach not only empowered JAI's QA team to customize fixtures with each product iteration, but also enabled rapid deployment through their digital inventory system. As a result, the lead time was drastically reduced from a week to a matter of hours, with the production of fixtures now being accomplished entirely on-site. The seamless integration of fixturemate and the automation of fixture creation brought tremendous efficiency gains and heightened agility to JAI's manufacturing processes.

How could design automation help you?

Measuring fixtures play a crucial role in ensuring precise and reliable part quality. You can optimize the design process for these fixtures using our web-based design automation software. Just input some basic settings, draw simple shapes using your mouse, and the software will produce a practical custom design that can save you a good chunk of time and money.

Discover how our design automation software can help you get the design results you want in half the time or less.

Explore related articles

Fixtures in modern manufacturing

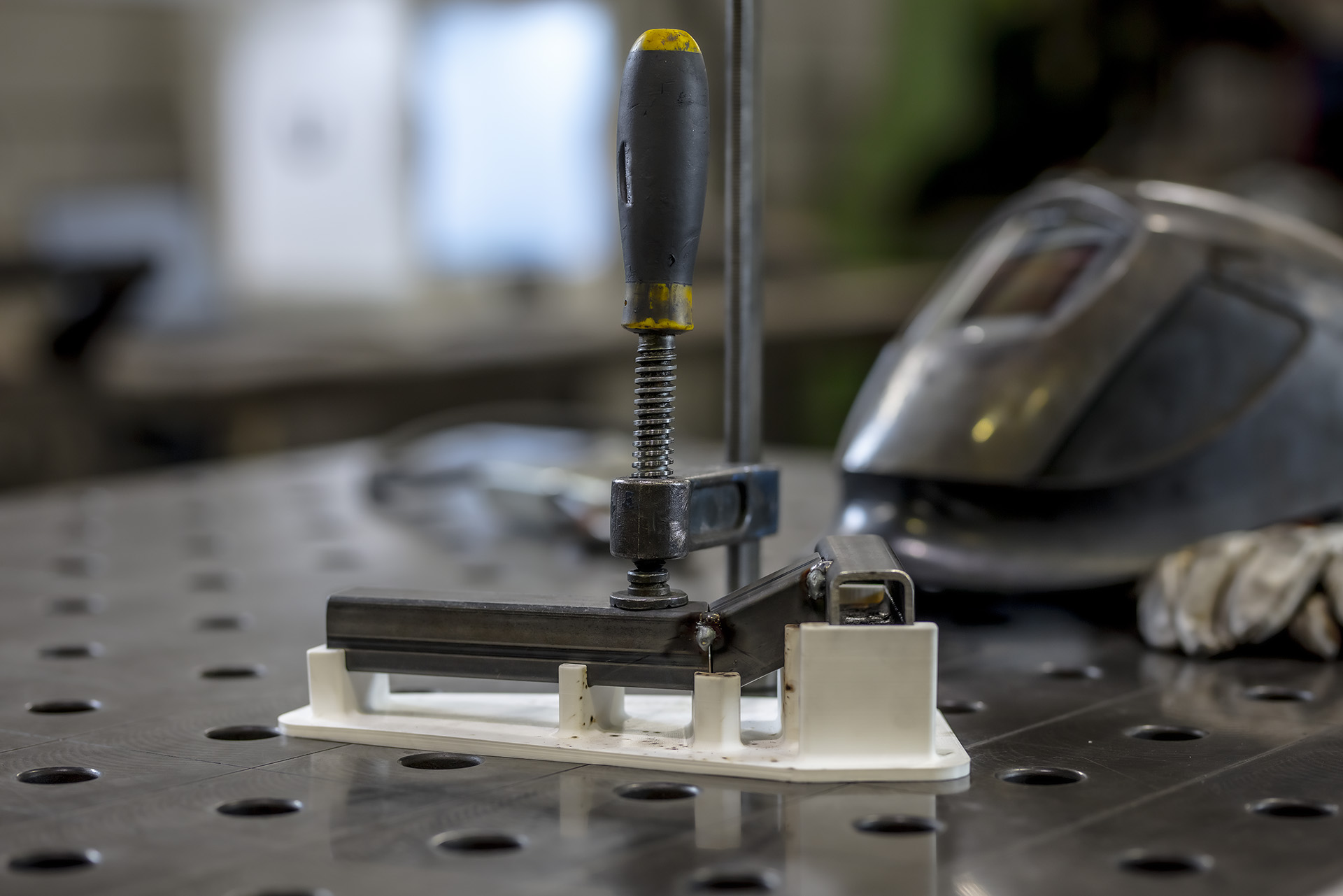

Design automation in use: Bonding and welding fixtures