Keeping tools and equipment organized is essential for smooth and efficient operations in various industries.

Tool organizers are used to securely hold and arrange various tools and equipment in a specific configuration. In production environments, time is money, and tool organizers act as reliable guides to ensure that each tool has its designated place for easy access while also keeping the workspace clutter-free.

A shadow board is a tool organizing system you’re likely to find in workshops and maintenance zones. These typically consist of a board or panel with outlines or "shadows" of different tools or equipment drawn on it. Each tool has its specific outline, indicating where it should be placed when not in use. You might also find a pocket with a corresponding shape for each tool to fit into.

The purpose of a shadow board is to visually guide workers on where to store each tool or piece of equipment when it is not being used. By having clearly defined outlines, it becomes evident when a tool is missing or not returned to its designated spot, making it easier to identify and prevent misplaced or lost tools. It also helps keep a tidy and organized workspace, saving time and enhancing efficiency by ensuring tools are readily available and easy to find when needed.

The benefits of tool organizers

Better organization. By securely holding tools in place, tool organizers ensure a tidy and systematic arrangement of equipment. This promotes better workflow and reduces the time spent searching for tools, which translates into saved costs.

Improved productivity. Organized tools lead to quicker access, minimizing downtime during work, and increasing overall productivity.

Cost-effective. Tool organizers prevent tool damage and loss, reducing the need for replacement tools and saving costs in the long run.

Safety and reduced accidents. Organized tools prevent the risk of injuries caused by scattered or misplaced tools, ensuring a safer working environment.

Increased tool life. Properly stored tools experience less wear and tear, prolonging their lifespan and reducing maintenance costs.

Customizable designs. Tool organizers can be tailored to accommodate various types and sizes of tools, making them adaptable for specific industry needs.

Space optimization. Organized tools take up less space, making the workspace more efficient and freeing up valuable real estate.

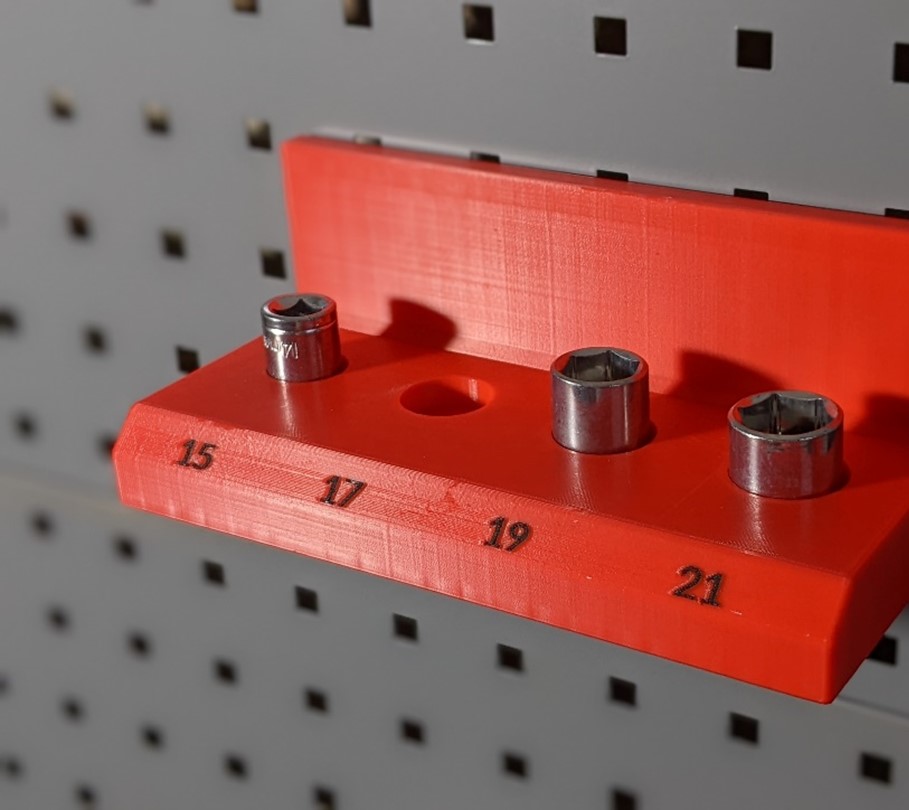

Visual management. Tool organizers with clear labeling enable easy identification and retrieval of tools, promoting better inventory management.

Versatility. Tool organizers can be used in workshops, manufacturing lines, construction sites, and various other industrial settings.

Streamlined processes. With tools readily accessible and well-organized, workers can focus on tasks at hand, leading to smoother operations and better project outcomes.

Tool organizers in use

Deutsche Bahn (DB), Germany's national rail network, encountered the challenge of efficiently creating shadow boards and organizing tools within their maintenance depots.

To address this, they set out to implement a system capable of generating nest geometries with minimal effort and expertise, so maintenance operators could independently create their own tool organization systems.

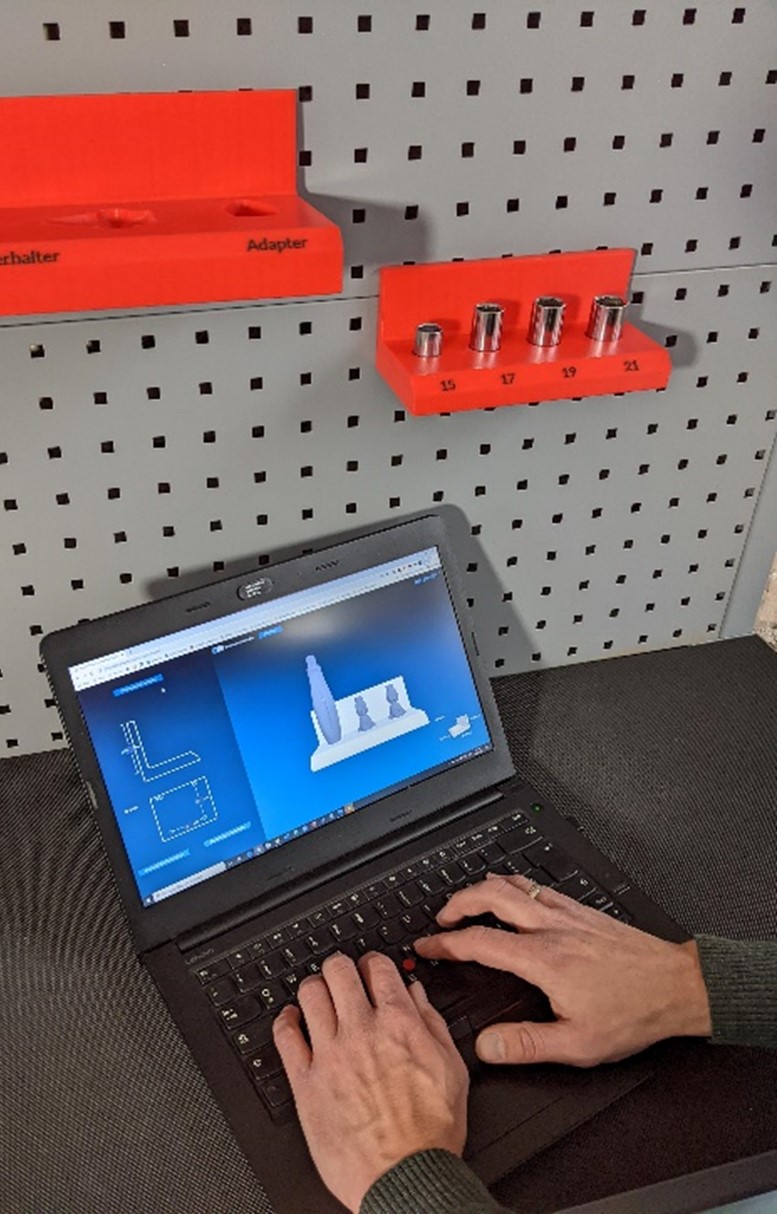

DB achieved this by integrating fixturemate and 3D printing into their processes, which resulted in significant advantages:

- Lead times for fabricating tooling were reduced by 40-90%, resulting in faster and more efficient processes.

- A newfound flexibility in conducting internal tooling operations enhanced adaptability and responsiveness.

- The creation of a digital inventory for the boards allowed for easy sharing and utilization across different work sites.

- The mass customization potential that 3D printing brings meant DB’s maintenance team could tailor tool organizers to suit specific users and operations, optimizing performance and productivity.

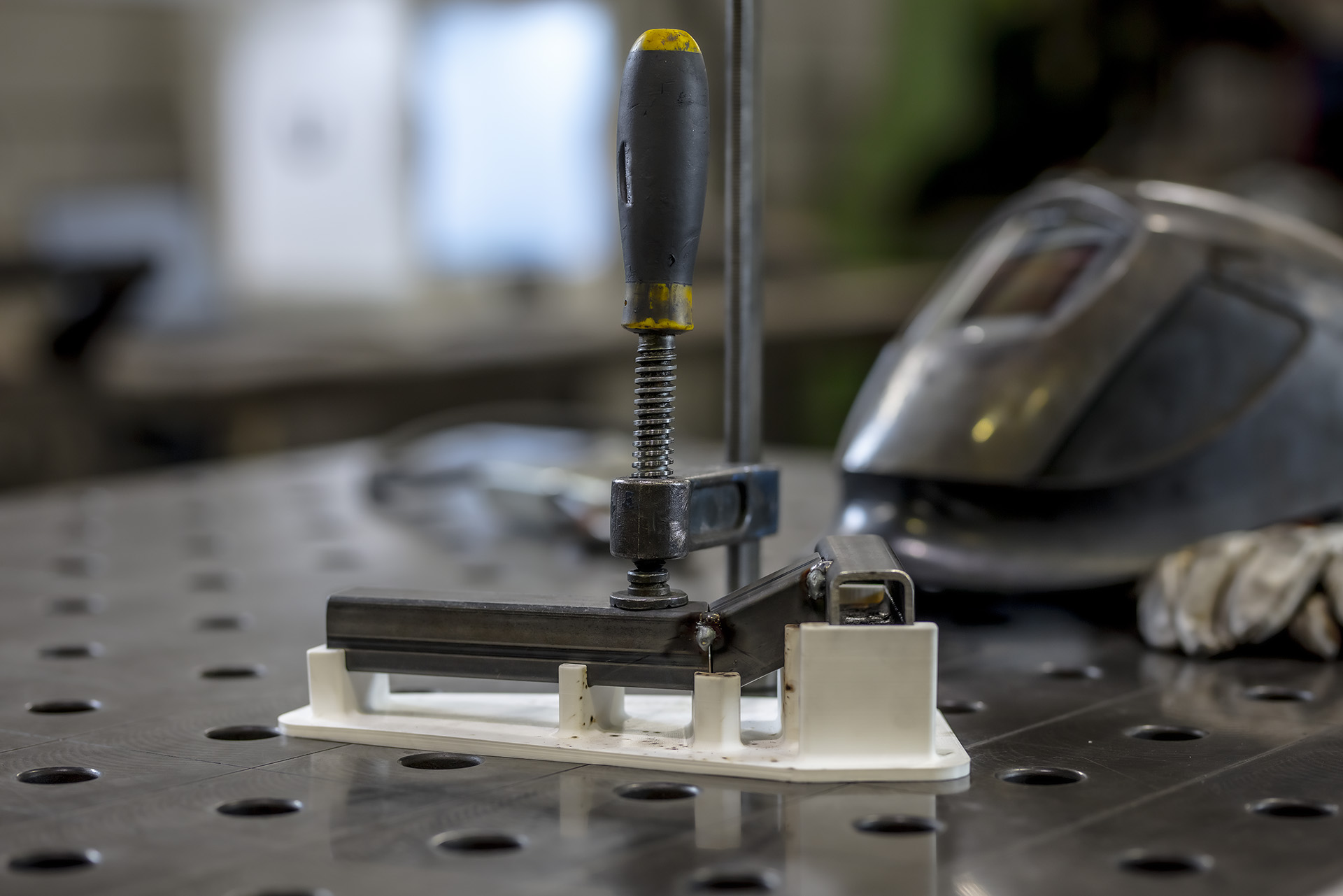

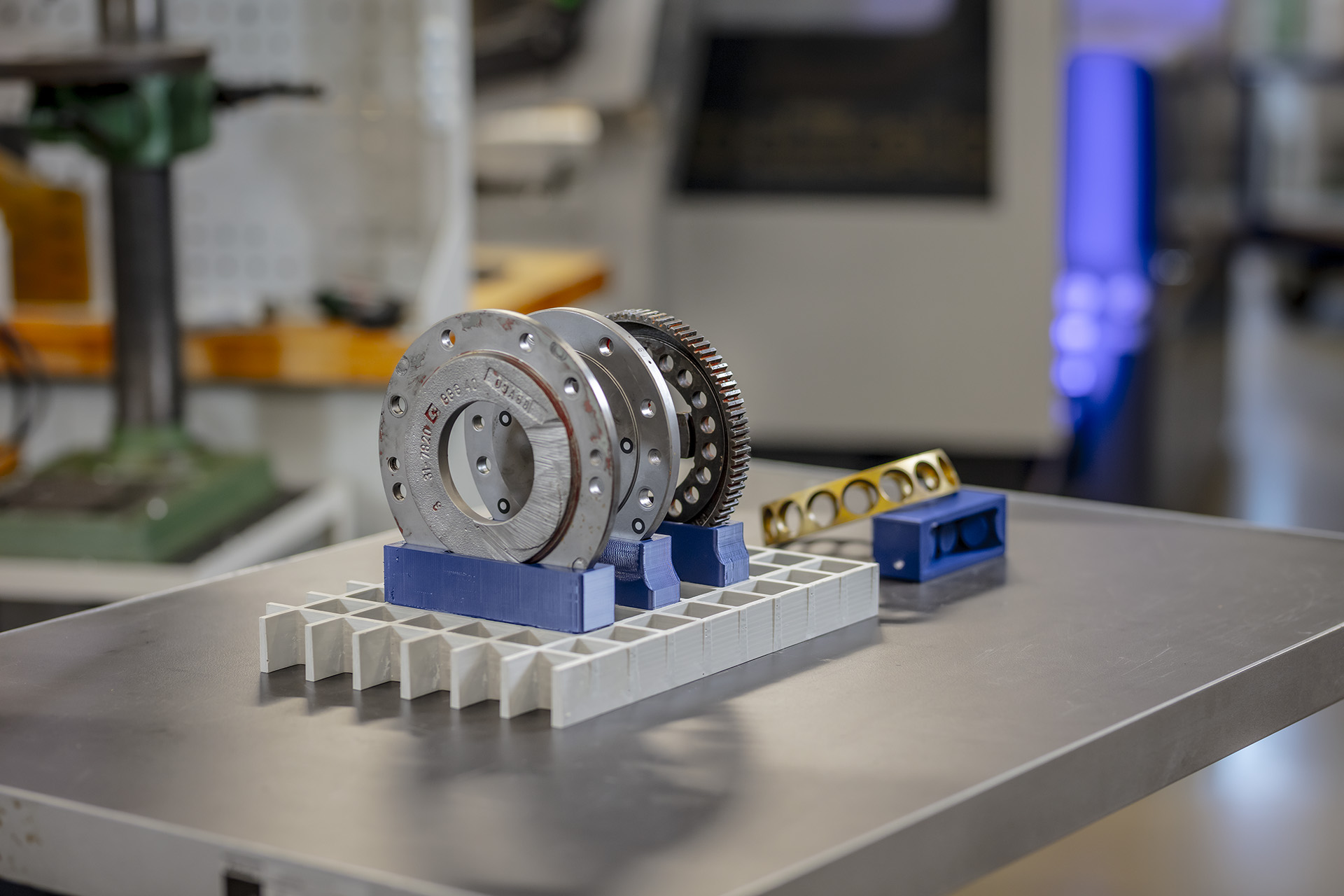

This may seem like a simple example, but through 3D printing and design automation, holders for specialized tools with irregular shapes can be designed, manufactured, and deployed across all sites within 24 - 48 hours.

Designs for custom tooling can be imported into fixturemate, and the geometry can be subtracted from a standardized tool organizer shape to create a perfect fit. Parameters like tolerances can be tweaked to create tighter or looser fits for each tool, so they are held firmly but are not too hard to remove and return when needed. Parts can also be 3D printed in different colors in order to distinguish a particular set of tools so they can be identified quickly.

Previously, a design task like this would have required specialized CAD skills and knowledge of DfAM (design for additive manufacturing). However, with fixturemate, the process becomes much simpler, empowering users outside the core design team to create and manufacture custom tooling without the need for extensive CAD knowledge.

Thanks to the powerful combination of design automation and in-house 3D printing, DB was able to expand its internal design processes and produce a wide variety of tool organizers for different assembly procedures within their own facilities.

How could design automation help you?

Tool organizers play a crucial role in optimizing workspace organization and improving productivity. You can automate the design of these parts quickly and easily using fixturemate, our web-based design automation software. All you need to do is upload your workpiece, configure standard design features, and the software will automate the rest - CAD expertise is optional!

Explore related articles

Design automation in use: Bonding and welding fixtures

Design automation in use: Carrier trays