Headquarters

Blomberg, Germany

Traditional design processes for copper inductors were time-consuming and costly, hindering efficiency and scalability in an era demanding rapid customization and shorter product life cycles.

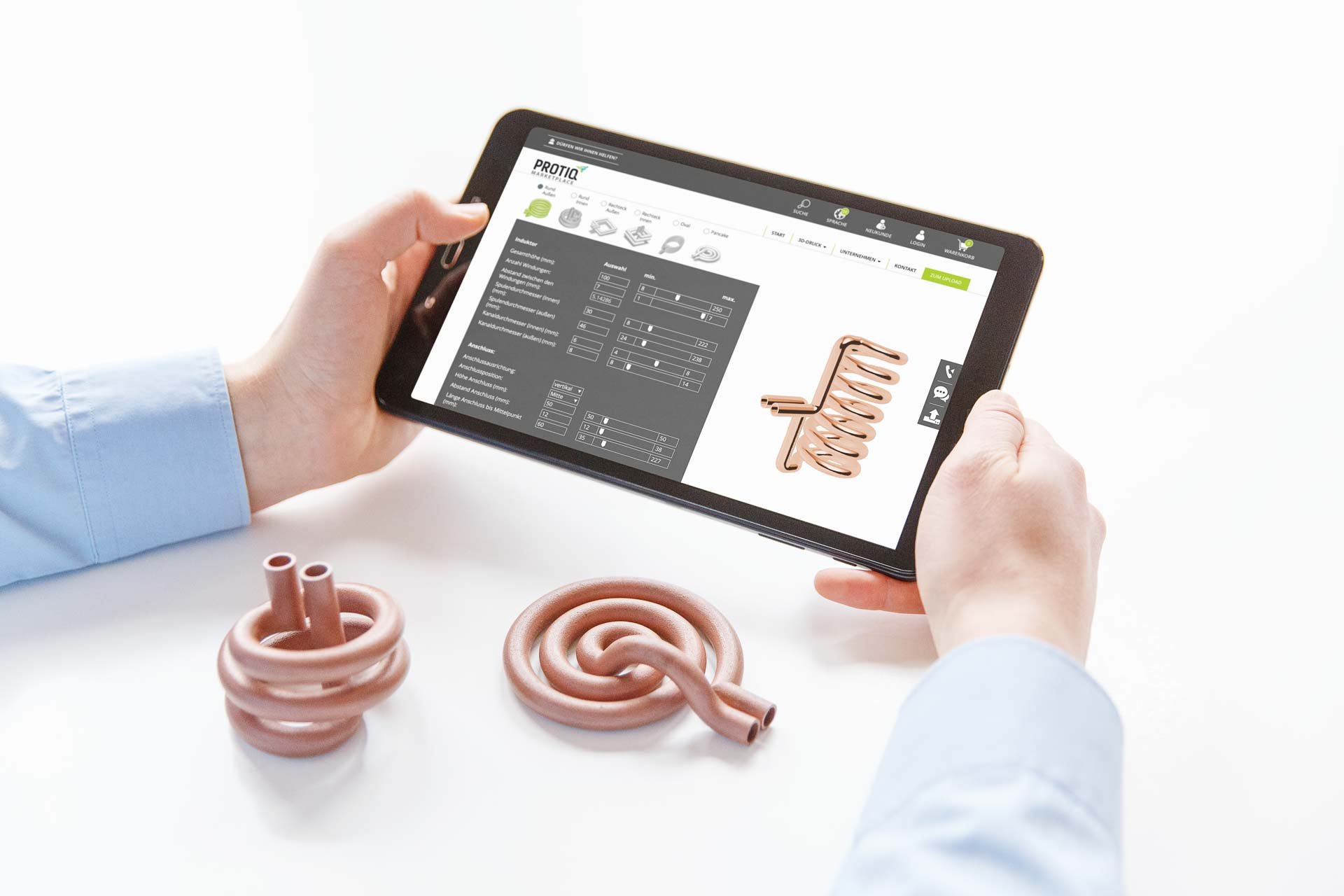

Utilizing trinckle's paramate technology, PROTIQ introduced a web-based inductor configurator, cutting design time from 3.5 hours to minutes, reducing costs by €350 per unit, and speeding up time-to-order from weeks to minutes, thereby unlocking scalable customization opportunities in industrial additive manufacturing.

Headquarters

Blomberg, Germany

Industry

Manufacturing Marketplace

Size

20+

Product

Custom solution

Use case-specific geometry for higher performance.

3.5 hours to 3 minutes, reducing design costs by 350 € per unit.

From two weeks to 10 minutes, plus live pricing within the configurator for direct online orders.

Copper inductors are tools used for metal processing in manufacturing industries using induction heating. Their coil geometry must adapt as precisely as possible to the shape of the particular metal workpiece to reach the best efficiency levels. The fact that additive manufacturing manages complex geometries including windings and ducts quite easily and considerably cheaper than conventional production processes like bending and brazing, makes copper inductors a perfect use case for additive manufacturing.

PROTIQ – a Phoenix Contact Company that has become a pioneer in industrial additive manufacturing – produces these customer-specific inductors using selective laser sintering for copper.

This seemed to be a promising business case if it had not been for one remaining hurdle: The design process of those individual inductor geometries. Generating those design variations in a conventional CAD design process comes along with many manual and recurrent design tasks. This time-and-cost-intensive workflow would have killed the business case for PROTIQ.

That was when Dr. Ralf Gärtner, Managing Director of PROTIQ, met us and learned about our paramate software platform. Based on paramate’s cloud-based architecture, we developed a web-based configurator for inductors that enables customers to intuitively configure and order customized geometries in a few minutes.

“The inductor configurator was tailored by trinckle to meet the exact requirements of our industrial customers. Users can simply select the required basic shape and determine parameters such as the number of turns, the coil diameter or the positioning of the connection plate according to their own application.”

MANAGING DIRECTOR PROTIQ GMBH

The inductor configurator is a plain example for design automation based on paramate. Instead of manual design steps in conventional, highly complex CAD tools, we use a parametric design approach and make it accessible in intuitive web applications.

Around 20 open parameters give full flexibility to the user to adapt the geometry exactly to his or her needs. At the same time, we take all interdependencies into account to ensure the functionality and printability of the geometry. There is no need for CAD experience or knowledge regarding AM-ready design. Configurators based on paramate eliminate the complexity of traditional product development. PROTIQ’s customers are integrated into the design process.

Moreover, prices of the inductors no longer have to be calculated in a separate process step but are shown instantly within the web application. The copper tools are ready to order. Sending requests and proposals back and forth belongs to the past.