Fixtures you can easily design with fixturemate

Fixtures are indispensable tools in manufacturing, engineering, construction, and other industrial contexts. They enhance productivity, reduce errors, and contribute to the overall quality of a final product or component.

Key takeaways

-

Fixtures stabilize and align parts for precise machining in operations like milling and drilling.

-

During assembly, fixtures ensure components are correctly aligned and secured, enhancing efficiency and accuracy.

-

In quality control, fixtures facilitate consistent, accurate measurements by providing a stable setup for inspection.

-

3D printing fixtures and other production tooling enhances development by reducing time, keeping control in-house, offering design flexibility, and allowing easy, low-cost replacements.

-

fixturemate software streamlines fixture design, saving time and costs, and enables the creation of custom fixtures with simple settings, requiring minimal CAD expertise.

In this article

How 3D printing streamlines the process

Develop fixtures faster with fixturemate

Tooling up challenges

Designing production tooling can be an expensive, time-consuming process which occupies your design team and puts bottlenecks in product delivery.

fixturemate can help you automate parts of this process, saving time spent on repetitive, time-consuming CAD operations, and freeing up your CAD design team for higher priority tasks. fixturemate is able to automate steps in the design process of fixtures for machining, assembly, measuring, bonding, welding, inspection, and more.

How 3D printing streamlines the process

3D printing your production tooling can streamline production tool development further. This fabrication method is seeing a rapid uptake by industry because it offers a number of benefits over traditional fabrication methods, including:

Reduced production time. 3D printed production tooling can shrink production time down to a matter of hours instead of days or weeks.

Control over production processes. Tool production stays in-house, without the need to outsource to third parties, and the lead times that accompany that.

Better design flexibility. Feedback and design changes can be quickly integrated and a new tool produced in a matter of hours on-site.

Easy to replace. If a tool should wear or break, it can be reproduced at low cost, at any quantity needed.

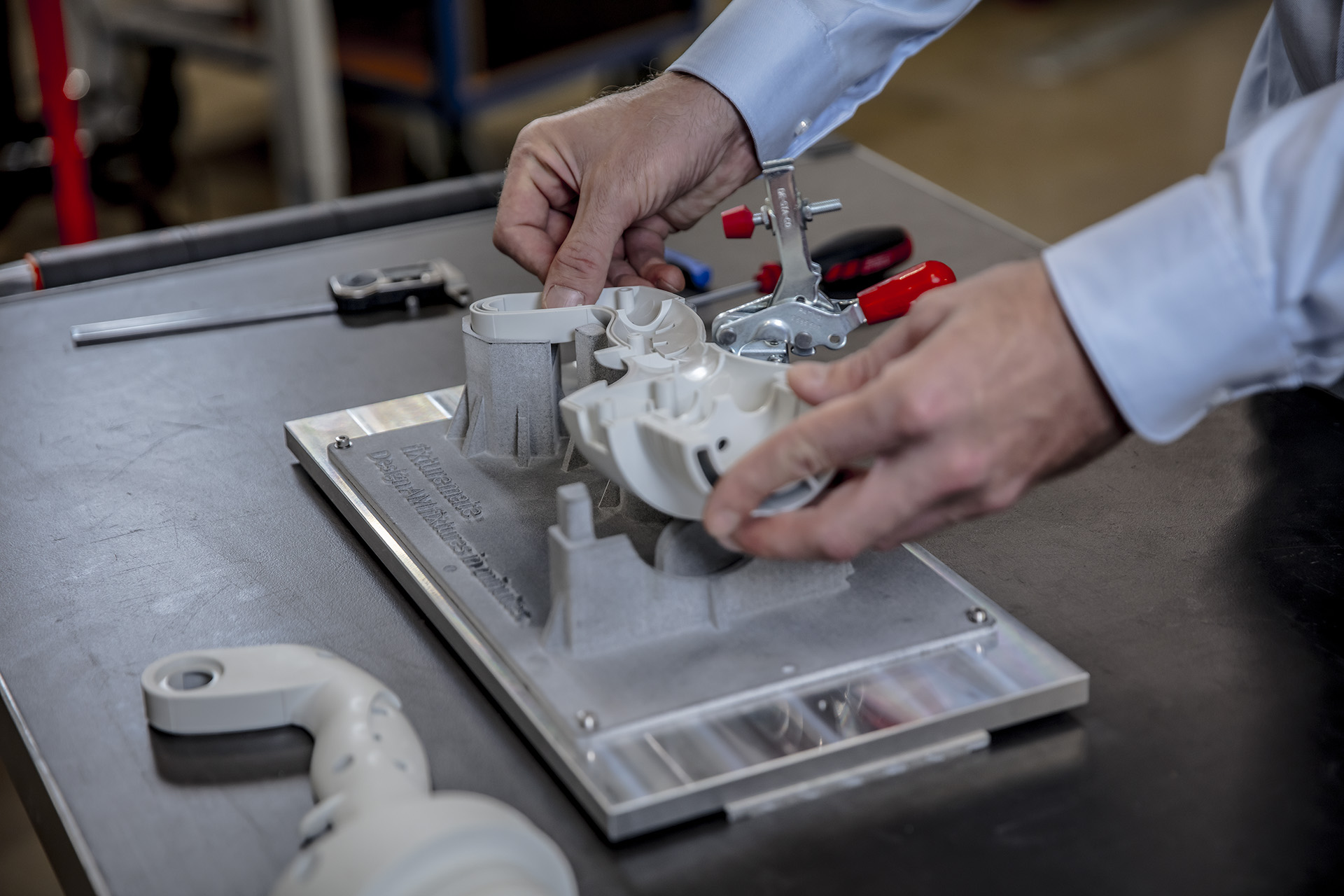

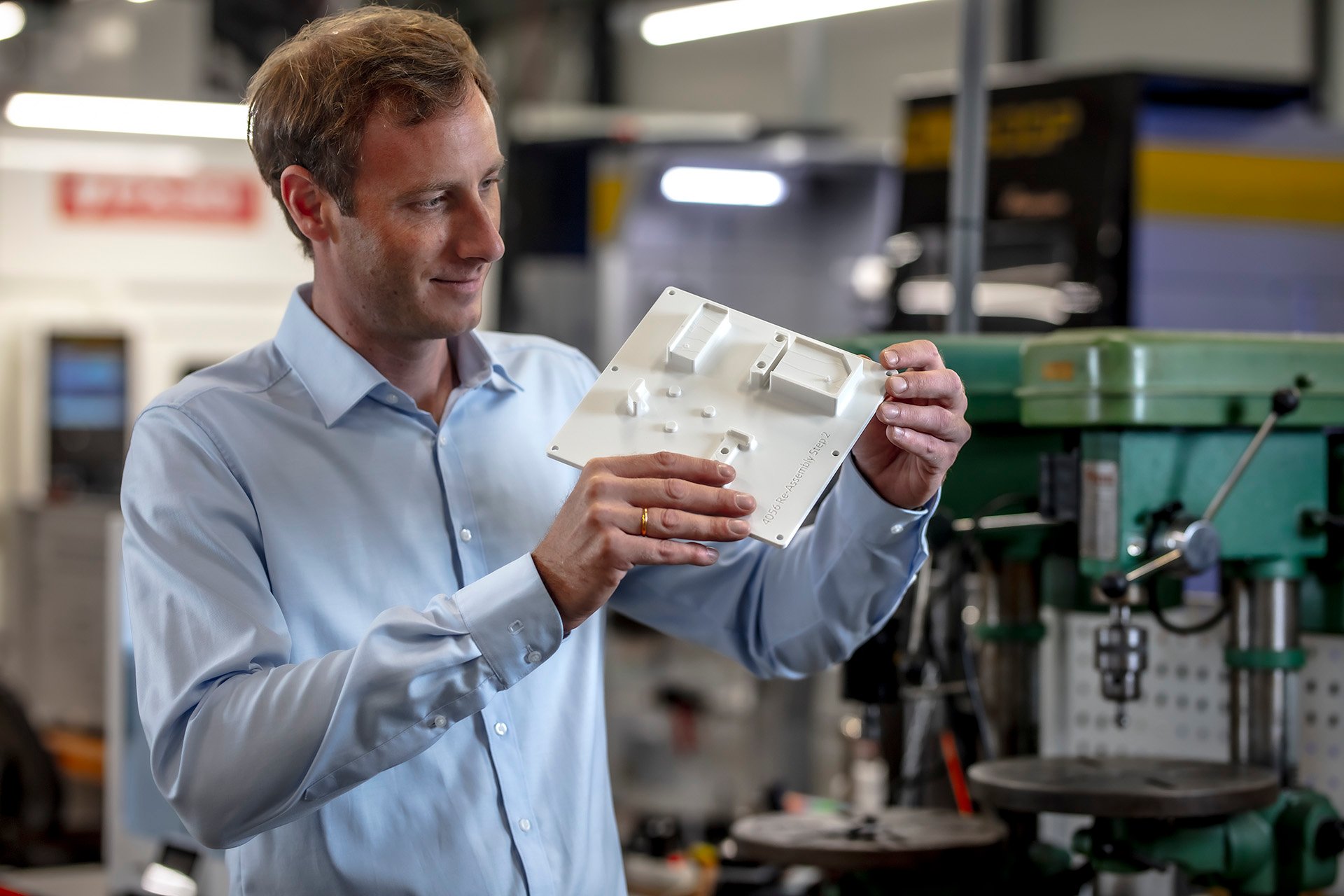

Custom fixtures can produced quickly and at low cost with 3D printing, streamlining production efficiency

Develop fixtures faster with fixturemate

fixturemate has been successfully used to speed up the design process for many types of production fixtures. Just import a part that needs fixturing, change some easy-to-use settings to suit your needs, and you can have a custom fixture designed in minutes. You don't need a CAD background to do it, and the software works directly in your web browser, so will work on any operating system.

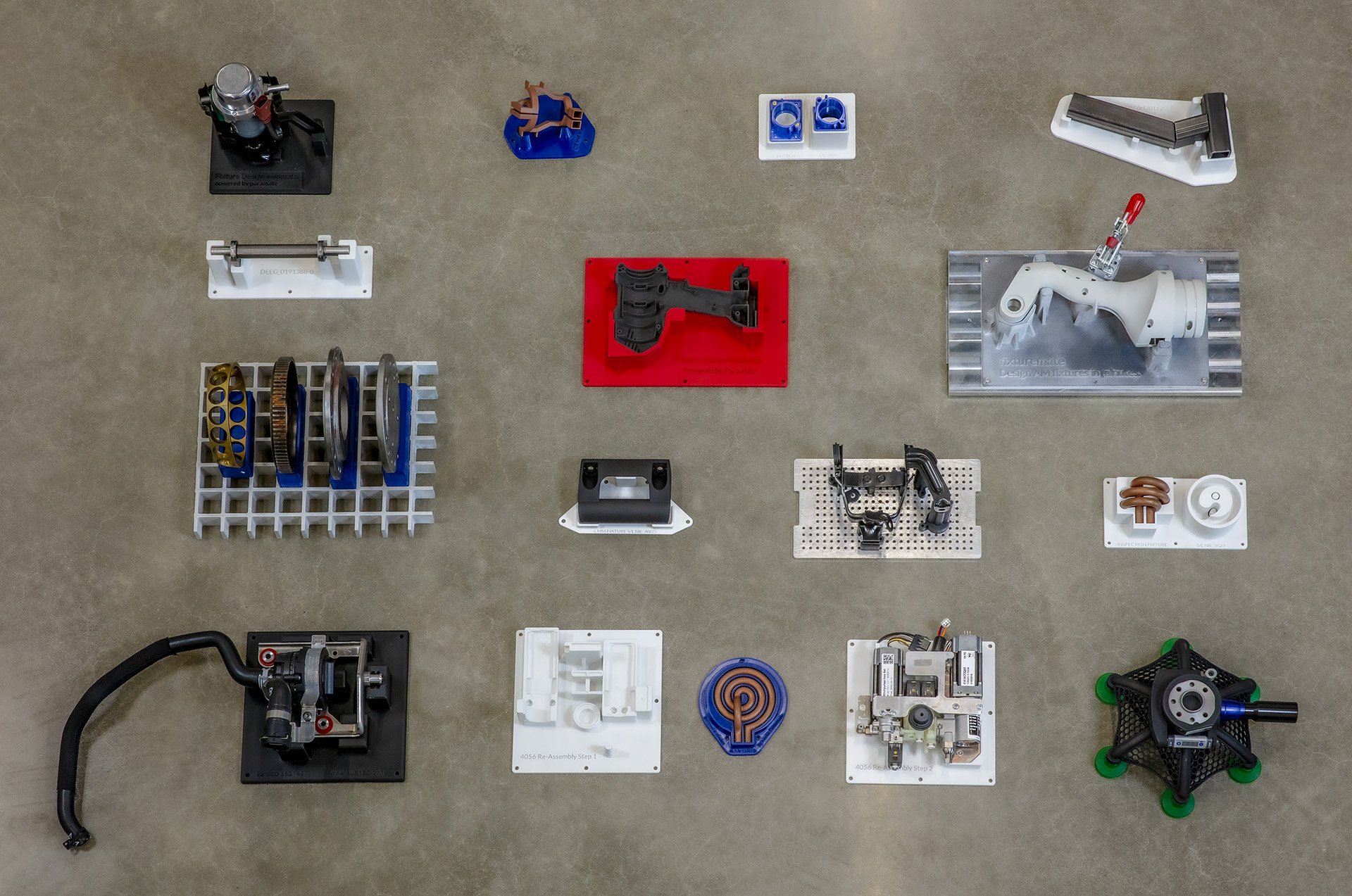

Below are some examples of common fixture types that fixturemate can help to design, saving you time, costs, and freeing up your design team for high-priority tasks.

Assembly fixtures

Assembly fixtures are valuable for complex or repetitive assembly tasks in industries like automotive, electronics, aerospace, and manufacturing. They ensure accurate part alignment and positioning of components, improving precision and reducing errors. Assembly fixtures enhance efficiency and productivity by providing a stable setup, allowing workers to focus on assembly tasks. They contribute to consistent quality and performance by maintaining uniform assembly methods. Additionally, assembly fixtures promote safety by securely holding components and minimise the risk of accidents. For large-scale production or repetitive assembly processes, fixtures enable scalability and reproducibility. While there is an initial investment, the long-term cost savings are significant due to increased efficiency, reduced errors, and lower production costs.

A 3D printed assembly fixture can improve assembly processes for custom products

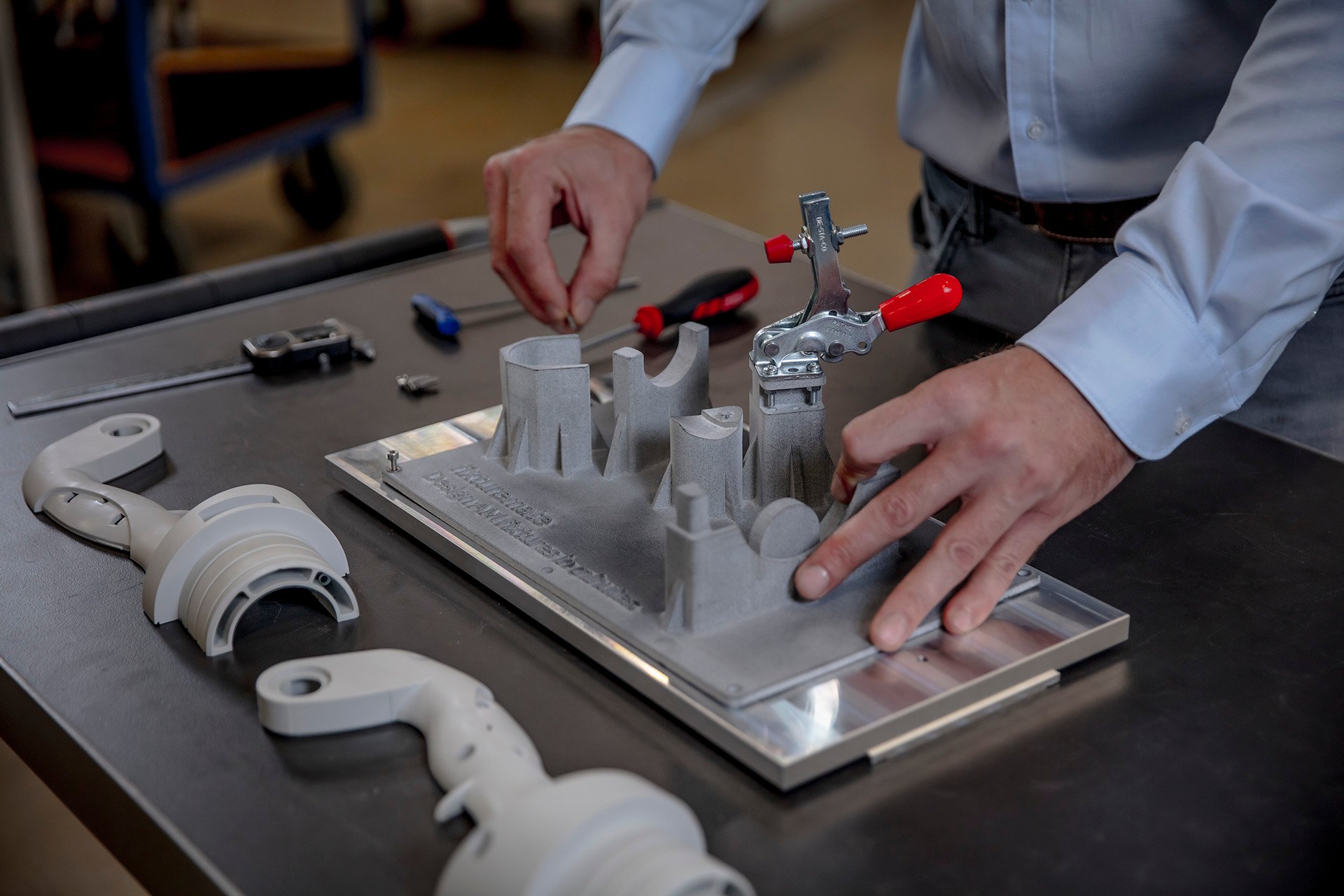

Machining fixtures

A machining fixture offers stability, precision, efficiency, safety, and cost savings in machining operations. It ensures accurate and consistent results by securely holding the workpiece, preventing movement or vibration during machining. With repeatable setups, it saves time and effort compared to manual adjustments. Machining fixtures enhance efficiency, improve safety by minimizing risks, and enable complex or multi-axis machining. They also lead to long-term cost savings by reducing errors and minimizing scrap parts. Overall, machining fixtures are vital in industries that require precise and efficient machining processes such as automotive, aerospace, manufacturing, and engineering.

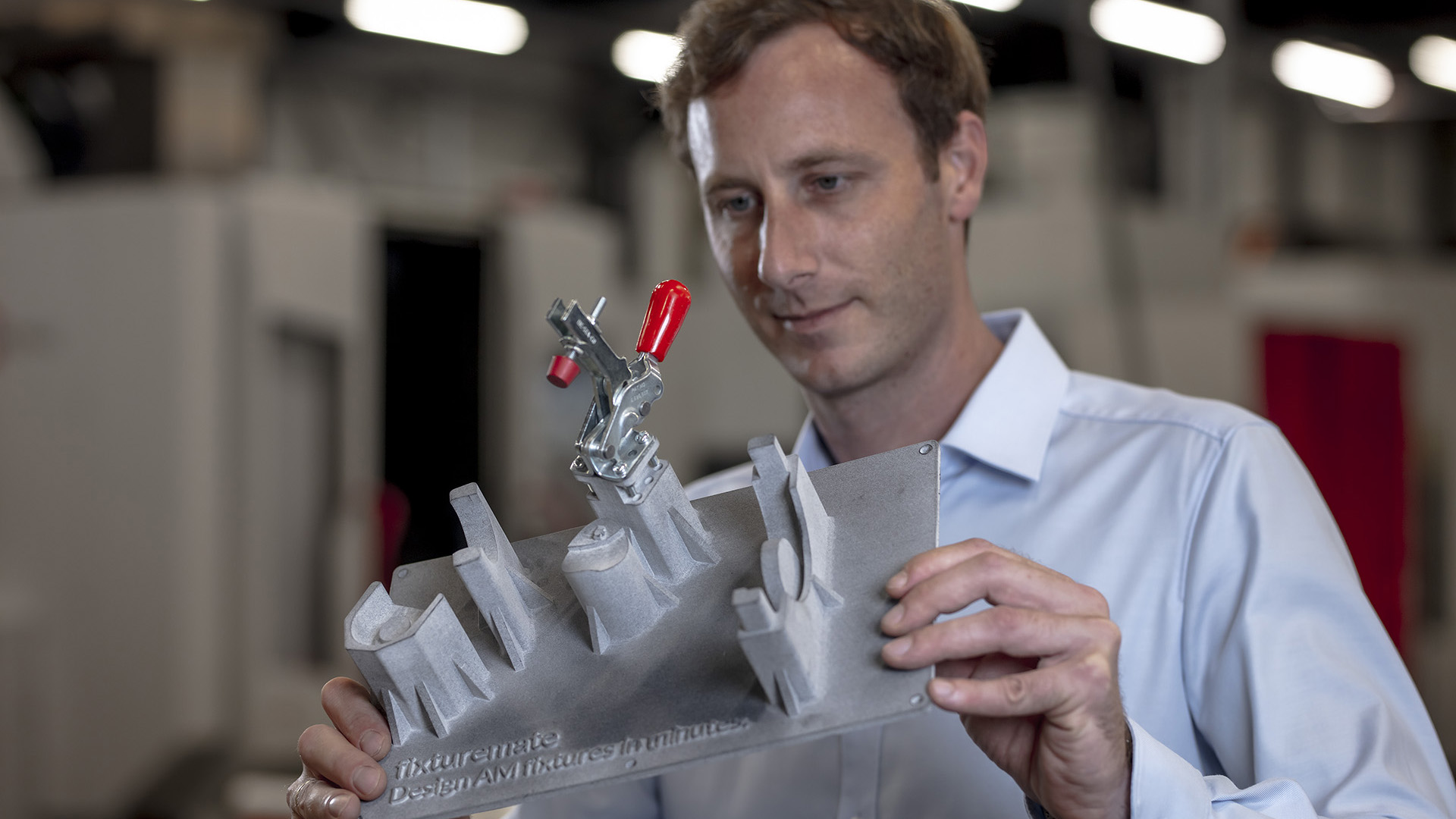

3D printed machining fixtures can achieve accurate results without expensive materials

Measuring fixtures

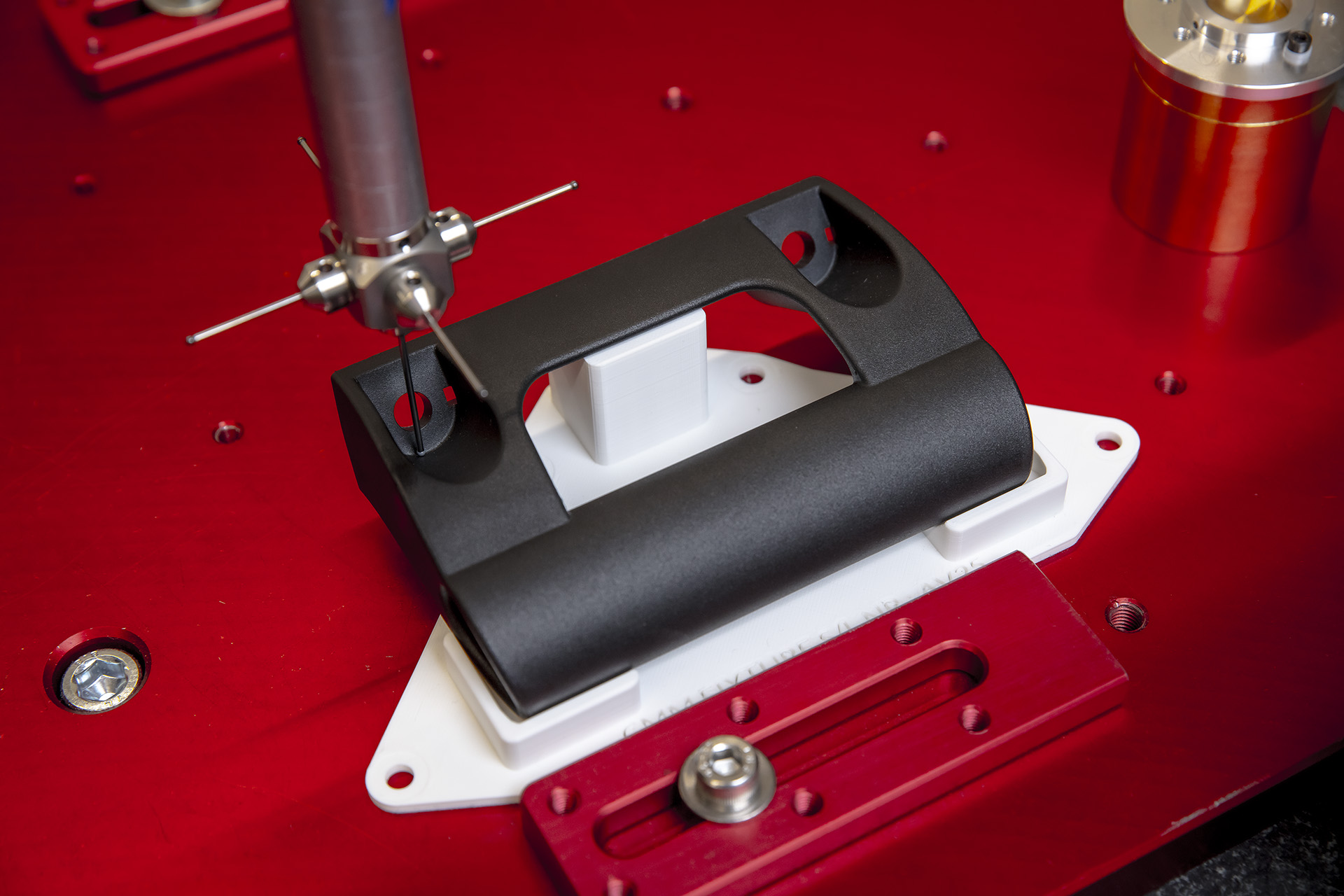

A measuring fixture is utilized for precise and reliable measurements in various industries to improve accuracy, repeatability, and efficiency. By securely holding the workpiece or the measurement target in a stable position, a measuring fixture eliminates the potential for measurement errors caused by movement or misalignment. It ensures consistent and repeatable measurements, reducing variability and enhancing quality control. In addition to this, a measuring fixture streamlines the measurement process, allowing for faster and more efficient data collection. Whether in dimensional inspection, quality assurance, or metrology applications, a measuring fixture plays a crucial role in achieving accurate and dependable measurements.

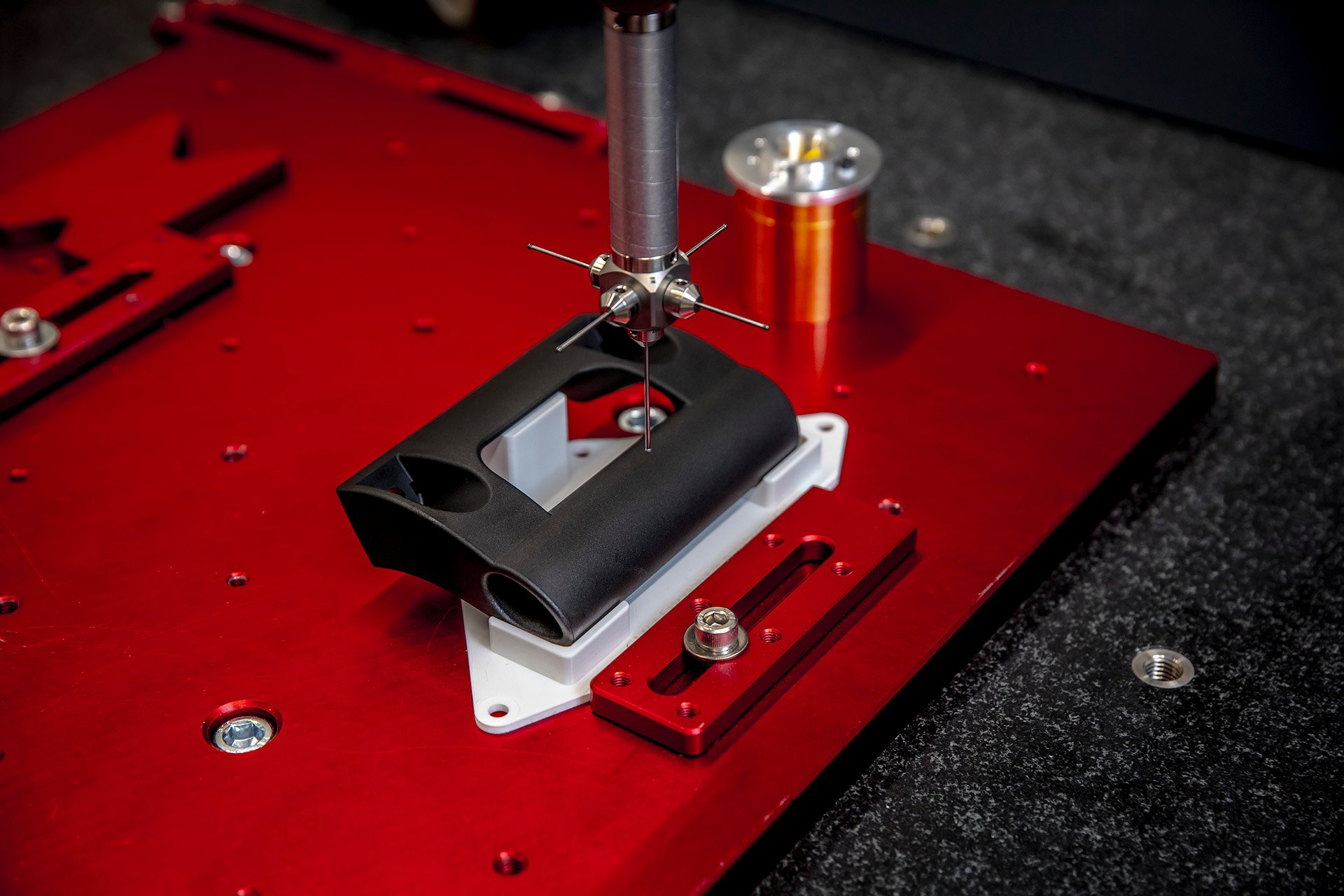

A custom 3D printed measuring fixture designed in fixturemate and used in a CMM operation

Tool organizers and shadow boards

A tool organization tray is a specialized tray or container designed to store and organize tools systematically. It provides a dedicated space for each tool, keeping them arranged, easily accessible, and protected. The tray typically has compartments or slots tailored to specific tool sizes and shapes, ensuring a secure fit. The primary purpose of a tool organization tray is to enhance efficiency and productivity by facilitating quick tool identification and retrieval. It eliminates the need to search for tools or deal with cluttered workspaces, saving valuable time and reducing the risk of misplaced or damaged tools. Tool organization trays are widely used in various industries, workshops, and garages to maintain a tidy and efficient working environment, promoting effective tool management and maximizing productivity.

Custom 3D printed tool organizers ensure quick tool access, eliminating time waste and improving workfloor safety

Bonding and welding fixtures

Bonding and welding fixtures play crucial roles in the manufacturing and assembly processes. These fixtures are specifically designed to securely hold and position components during bonding or welding operations. Bonding fixtures provide precise alignment and clamping mechanisms to ensure proper adhesion and bonding of materials such as metals, plastics, or composites. They facilitate consistent application of adhesive or bonding agents, resulting in strong and reliable bonds. Welding fixtures, on the other hand, are tailored for welding operations and provide stable support and positioning of workpieces. They ensure accurate alignment and accessibility for welders, promoting precise and consistent welds. Bonding and welding fixtures improve productivity, enhance quality control, and contribute to the overall efficiency and reliability of bonding and welding processes in various industries such as automotive, aerospace, construction, and manufacturing.

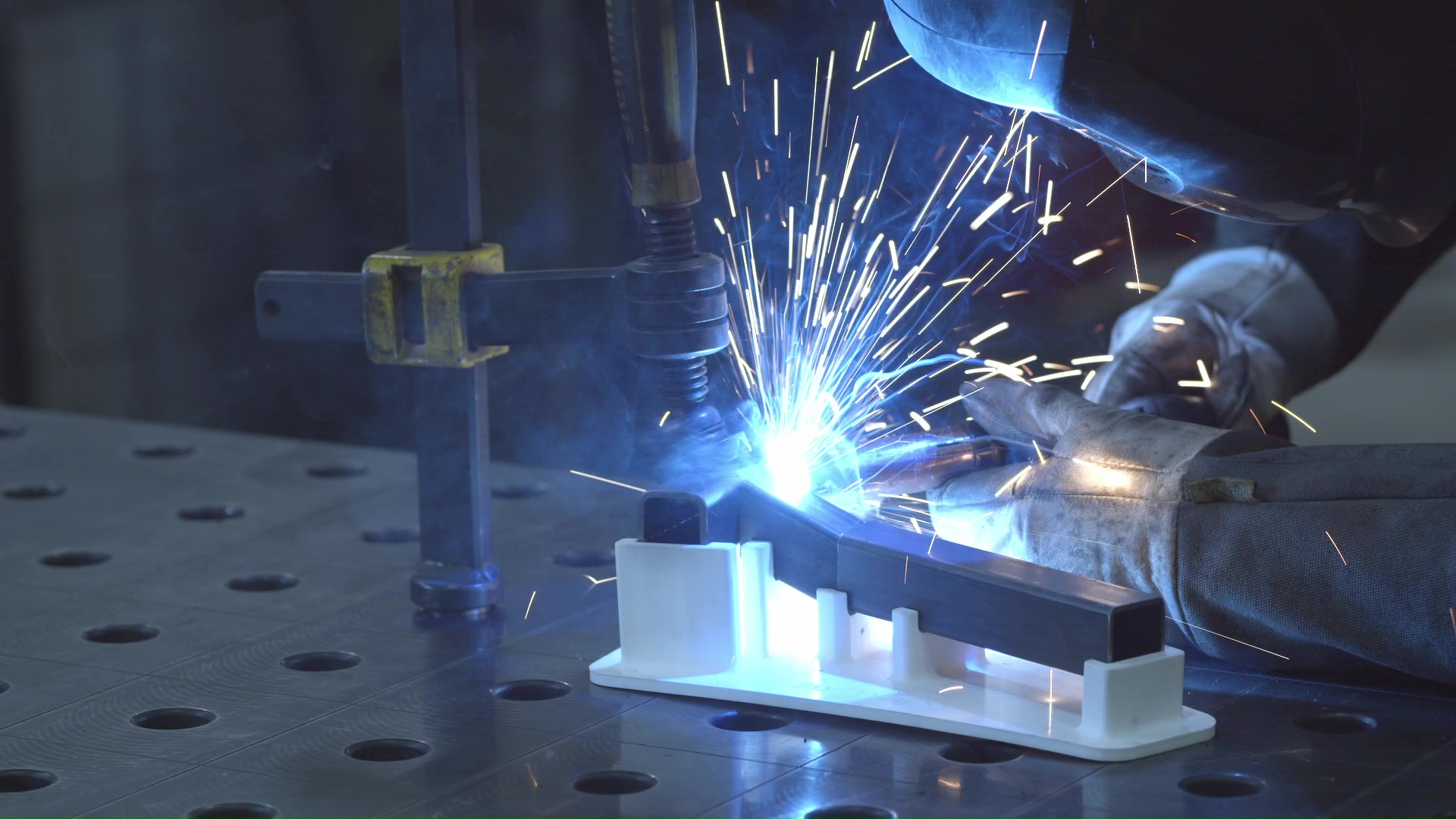

Custom 3D printed welding fixtures keep parts secure and accurately aligned during a welding process, and can be produced at low cost

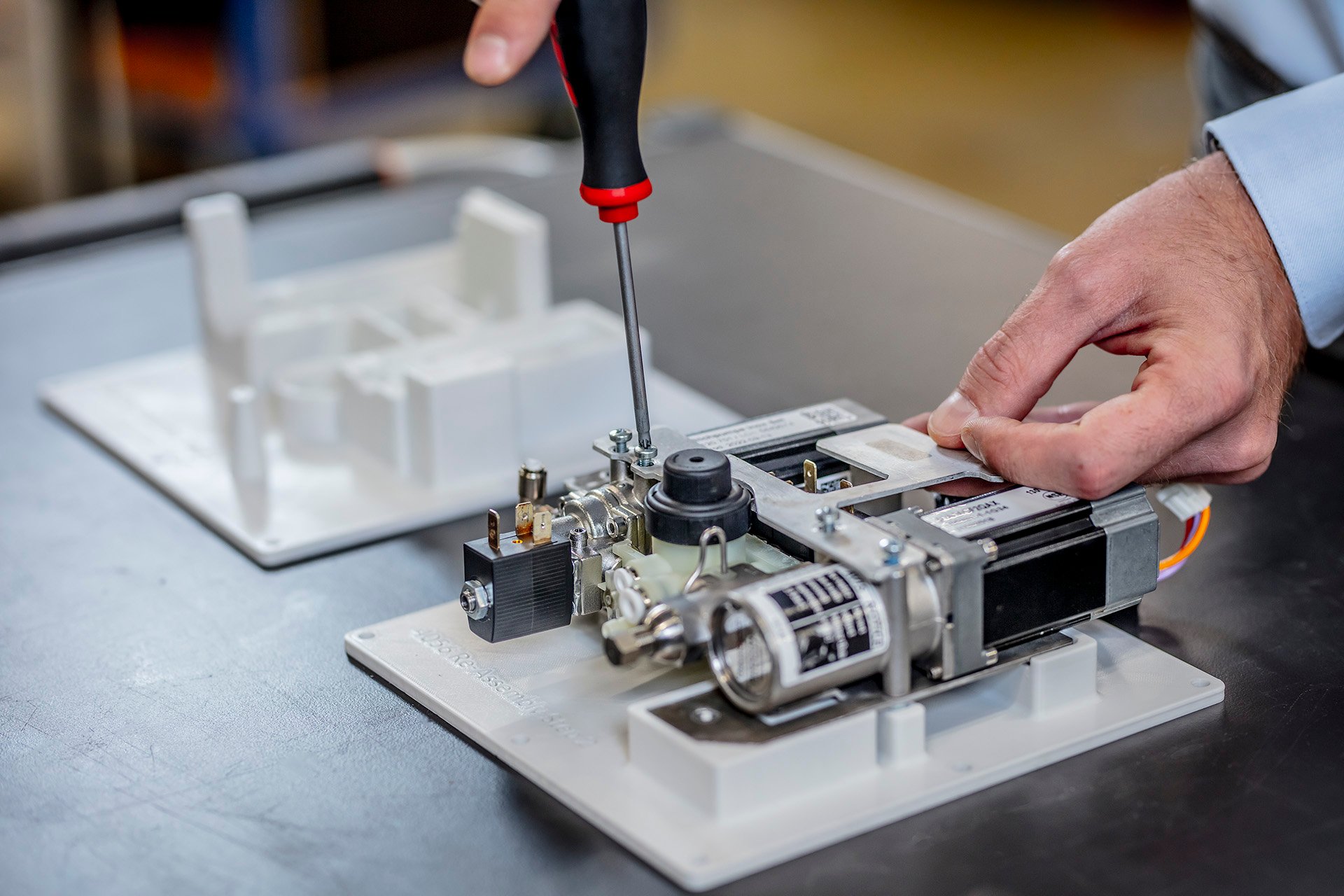

Inspection fixtures and gauges

Inspection fixtures and gauges are essential tools in quality control and inspection processes. These fixtures are designed to accurately and consistently measure and inspect various components and workpieces. Inspection fixtures provide a stable and controlled setup, allowing for precise positioning and alignment of the workpiece during measurements. They often incorporate specialized features, such as pins, probes, or contact points, that facilitate easy and accurate measurement of critical dimensions or features. Gauges, on the other hand, are specific measurement tools used to check the conformity of a component or workpiece to predetermined specifications. Sometimes referred to as 'go or no-go gauges,' these tools are essential in determining whether a part meets the required standard for continuing production. They provide a reference for comparing measurements and ensuring that parts meet the required tolerances. Inspection fixtures and gauges play a vital role in maintaining quality standards, identifying defects or variations, and ensuring consistent product quality in industries such as manufacturing, automotive, aerospace, and electronics.

Sometimes referred to as 'go or no-go gauges,' inspection gauges are essential in determining whether a part meets the required standard for continuing production

Carrier trays

A carrier tray is a versatile tool used for organizing, transporting, and storing various items or components. It typically features compartments, slots, or dividers that allow for secure placement and separation of objects. Carrier trays are widely used in industries such as manufacturing, logistics, and healthcare. They provide an efficient way to handle and transport small parts, electronic components, medical instruments, or delicate items. Carrier trays ensure protection against damage or loss during transportation, facilitate inventory management, and promote organization in workspaces. Using fixturemate, they can be customized to fit specific products or requirements, offering a practical and reliable solution for efficient material handling and storage.

A 3D printed carrier tray in an industrial tote, used to keep railway parts securely held during transit

Find out more

By automating parts of the fixture design process, fixturemate saves valuable time and costs, allowing your design team to focus on high-priority tasks. The web-based software streamlines the creation of custom fixtures without requiring extensive CAD expertise. With fixturemate, you can import your parts, adjust some simple settings, and have a custom fixture designed and produced that same day.

Explore related articles

Fixtures in modern manufacturing

Design automation in use: Measuring fixtures